In order to understand tax stamps and the process for ensuring secure and safe tax stamp application, there are a few components you must first understand. In this blog we’ll cover what a tax stamp is and what makes it different from other consumer stamps. We’ll also share common industries who may use tax stamps and identify automation equipment that could increase your packaging efficiencies.

Pharmaceutical Carton Labeler

Precise Labeling for Cartons and Packaging

Best recommended with the 103HSM+ Label Applicator.

Similar to other types of packaging, such as corrugated boxes, applying labels to cartons requires precision and accuracy. Your packaging is the most visible place most customers will see your brand. So, it’s important to make a professional impression. Labels are also the main way you can communicate important details about your product. For example, when labeling pharmaceutical cartons, it’s crucial to include all required information accurately and clearly.

An integrated labeling system will help your business achieve reliable, accurate, appealing labels on your carton packaging. A well made system can also improve your production speed and efficiency. This saves you time and money, all while upping the quality of your final product.

MTF Label Applicators

If you are looking for a carton labeling machine with pinpoint accuracy, micro-tension control, and a compact but powerful design, then MFT Automation has the solution for you. Our 103HSM Label Applicator offers the speed and accuracy required in today’s competitive production environment.

Pharmaceutical Labeling Requirements

The United States Food and Drug Administration (FDA) provides many labeling resources for the labeling of prescription and over-the-counter medications. Mandatory information must be included on the label for any carton or container for human prescription drugs.

Some examples of required information include:

- Proprietary name

- Warnings and precautions

- Usage and dosage details

- Drug interactions

- And more

You should always check the FDA’s requirements for your specific medication or product types.

Bucket Labeling Solutions

Best Recommended with the Impresso Bucket Label Applicator and Conveyor

Many industries rely on buckets to store and transport their materials and products. No matter which type of business you run, it’s important that your bucket labeling system is reliable, quick, and precise.

The best way to ensure your products are labeled correctly is with an adaptable system. MFT machines are modular in design and can be integrated with a variety of accessories for different applications. MFT Automation machines can be easily adjusted to your exact container’s size, hold it precisely in place as a label adheres. The bucket labeler is a fast system that can accommodate a variety of different label types, such as wrap-around labels or flat side labels for rectangular buckets.

Depending on your current facility, our Bucket labeling system can be a standalone system or integrated into a larger production line. MFT’s engineering capabilities are strong and we pride ourselves on the ability to engineer an automation solution designed for your production needs.

Impresso Bucket Label Applicator and Conveyor Use:

MFT Automation systems offer high performance, reliable production, and cost effective solutions.

-

- Customizable computer controls with separate enclosed on-board panel. The all-in-one self-contained electronics software platform is flexible to run many different types of applications.

- Brushless Servo Motor for long life. The Impresso Labeler and the Bucket Drive Roller utilize a brushless servo motor for accurate placement and precise control. 1000 watt motors are available for the most demanding applications. Motor upgrades are available depending on the application.

- Transports buckets while precisely applying labels. The Bucket Drive Roller next to the peel plate rotates the bucket as the label applicator applies the label. A centering assembly opposite the Bucket Drive Roller extends towards the bucket and holds it in place as labels are adhered.

For further information about your production needs, give us a call at 651-407-3100.

Want to See How your Product Integrated

with our Machines?

Send us a sample and we will make a demo video showing how your products feed through our machines.

Jar Labeling Machine

Best Recommended with the Impresso Bottle Labeler

While packaging your product in a jar might seem simple. But there are countless factors and choices between the beginning of manufacturing and the final product that your customer picks off the shelf. One of the most impactful elements on your jarred product is its label. Whether you use glass or plastic jars, cut-to-size, or rolls of labels – all that matters is the impression you make on the customer.

That’s why it is so important to have a reliable jar labeling machine for your production process. If you’re looking for a labeler that adapts to your needs, exceeds sanitation standards, and applies labels accurately every time, then you’ve come to the right place.

Impresso Bottle Labeler Use:

You have plenty of options when it comes to labeling your commercial jars, especially for food products. the two main types of jar labels are cut-t0-size, which come in one continuous sheet and can be cut to any width you need. Most manufacturers opt for a roll of labels that are pre-cut. This saves on time and creates a more unified look. Within those two options, there are countless varieties of labels. You might use die-cut labels for simple projects or metallic labels to stand out on the shelf. Labels can be waterproof or vinyl for added quality. No matter what type of label you are applying to your jars, make sure to use a labeler machine that is adaptable, quick, and accurate.

Food Label Requirements

If you are packaging food in your jars, then it’s important that their labels contain all required information. There are 5 main elements in a food packaging label.

- Statement of identity

- Net weight

- Handling statement

- Manufacturers address

- Ingredients list

- Nutrition facts

For further information about your production needs, give us a call at 651-407-3100.

Want to See How your Product Integrated

with our Machines?

Send us a sample and we will make a demo video showing how your products feed through our machines.

Wine Bottle Labeler

Wine Bottle Labeler

Pressure Sensitive Labeling for Glass Wine Bottles

Best recommended with the MFT Bottle Labeler System.

Whether you distribute a national brand or maintain a small artisan shop, you know that the label on your wine is the first thing that attracts a customer. You carefully picked colors, text, and images tell your wine’s story. Your label also ensures that all mandatory information is included on your product. With so many important factors tied to one sticker, it’s crucial to have an efficient wine bottle labeler system in place.

MFT Bottle Labeler System

If you are looking for a wine bottle label machine with pinpoint accuracy, pressure sensitivity, and adaptable components, then MFT Automation has the solution for you. Our Bottle Labeling Machine features the superior Impresso Labeler to ensure precise label placement at high speeds. This stainless-steel portable machine is perfect for any commercial wine bottle labeler need.

Required Wine Information

The United States Alcohol and Tobacco Tax and Trade Bureau oversee the mandatory information to print on wine bottles. Wine, plus cider and mead, must be properly labeled before it can be sold in the United States.

Required information includes brand name, class or type designation, alcohol content, a health warning statement, and more. The best way to include all of this information neatly on your product is with an automated wine bottle labeler. A good labeling system should be pressure sensitive, so it doesn’t damage glass bottles. It should also be accurate, reliable, and easy to changeover between labels.

Credit Card Gift Card Labeling System

Best Recommended with our Impresso Labeling System for Credit Card and Gift Card Labeling Systems

Cashless payments for everyday use are on the rise. This is why credit card, debit card, and gift card manufacturers are seeing an increase in demand. As demands increase, so does room for error, such as the misapplication of removable activation labels. And with each error your customers face, the perception of your company decreases.

Impresso Labeling System Use:

This is why we created the Impresso Labeling System — a labeling machine that accurately places stickers on credit and debit cards. This system is appropriate for the following applications:

-

- Credit card stickers

- Credit card labels

- Debit card stickers

- Debit card labels

- Other activation sticker and labels

This labeling system is also mobile and compact; which gives it the ability to fit in various production lines and factory layouts. Its technology ensures consumers will be able to easily remove the credit card sticker without any trace of residue.

The Impresso Labeling System is used by card producers around the world due to its accuracy and quality placement of card activation labels. If you’re looking for a high performance and quality credit card labeling system that can do the same for you, this is the machine for your factory floor.

Ready to see the labeler in action? Click here or on the button below to send us a sample of your product and we’ll create a demo video of it being fed through the Impresso Labeling System.

Want to See How your Product Integrated

with our Machines?

We perform video demos for serious inquiries that are interested in receiving a video

demo showing how well our machines work with your product.

Security Labels

Best Recommended with the Impresso Labeler Integrated with an ip3 Friction Feeder

At Multifeeder Technology, our high performance label applicators are easy to use, compact, and suitably mobile to fit into tight production areas. Our industrial labelers apply labels at high speeds with accurate quality label placement, for numerous industries such as the pharmaceutical, cosmetic, food and beverage, packaging and print, and more. A perfect option is our Impresso Labeler integrated with an ip3 Friction Feeder.

Impresso Labeler Integrated with an ip3 Friction Feeder Use:

Security labels are adhered or attached to personal items or products to add security protection and tamper evidence. These labels have pressure sensitive adhesive, are easily applied to surfaces, and have a face material that accepts being printed with a barcode or other information. There are many different kinds of security labels on the market for numerous different situations.

Tamper-resistant labels are used when sending sensitive documents by way of envelope. A tamper evident seal will clearly and easily show whether anyone has attempted to gain access to documents or any other important envelope contents. The security labels or stickers can show a tear, can disintegrate, or can leave behind a message that access has been attempted by leaving various hidden patterns or words on the surface of the product, or can even show that a seal has been broken in a door, window, or cabinet.

RFID (Radio-Frequency Identification) labels are another form of Security label. A micro-chip and an integrated antenna are embedded into the label in order to send information to a receiver. With the miniaturization of electronic technology today, these labels can be quite flat or encased in a small plastic shell, and are used extensively in retail stores.

Another interesting feature of an additional type of security label is the label’s detection of water contact. Water-sensitive security labels are designed to dissolve or change colors upon evidence that water-related tampering has occurred. This type of security seal is a great option for protecting water-sensitive products, such as electronics that may be compromised if they come into contact with water.

In today’s world, where safety and security is foremost, security labels fulfill an important need for prevention and protection.

For further information about your Security Label production needs, give us a call at 651-407-3100.

Want to See How your Product Integrated

with our Machines?

Send us a sample and we will make a demo video showing how your products feed through our machines.

Scratch Off Labels & Cards

Best Recommended With an Impresso Labeler with an ip3 Friction Feeder for Scratch Off Labels and Cards

Scratch off labels consist of a clear permanent adhesive backing with a pigment applied on top that is adhered to a card. This enables the user to physically scratch off this material, which conceals a number or other coded information, for either entertainment or security purposes. Cards with scratch off labels are interactive for the user, and can be designed in many different shapes, sizes, and colors. These cards are also multipurpose, as they are used in advertising and marketing for promotional uses, sweepstakes, gambling, phone cards, and much more. In the case of gambling and sweepstakes, the cards give the user a hopeful anticipation of possibly seeing a winning message underneath, once the scratch-off material is removed. Scratch off labels can be affixed to bottles, direct mail marketing pieces, retail products, and so many more items in nearly every industry. These labels are extremely effective in driving sales and customer engagement, drawing the customer back to make repeat purchases again and again.

Impresso Labeler with an ip3 Friction Feeder Use:

MFT Automation’s feeders and labelers automate the production of Scratch Off Labels/Cards, or apply pre-manufactured Scratch Off Labels to the cards, with great ease, precision, and accuracy onto a production assembly line. Many manufacturers are still using outdated hand labor in their production facilities. Using our high performance Impresso Labeler integrated with an ip3 Friction Feeder automates the Scratch Off labeling process, providing long production runs with high quality accurate product placement for a complete automation solution. Automating Scratch off production lines with MFT Automation’s machines will save you time and money in production costs – with uninterrupted product assembly, an accurate system to record and print from a variable data database, and the ability to verify and reject products without error.

For further information about your Scratch Off Label production needs, give us a call at 651-407-3100.

Want to See How your Product Integrated

with our Machines?

We perform video demos for serious inquiries that are interested in receiving a video

demo showing how well our machines work with your product.

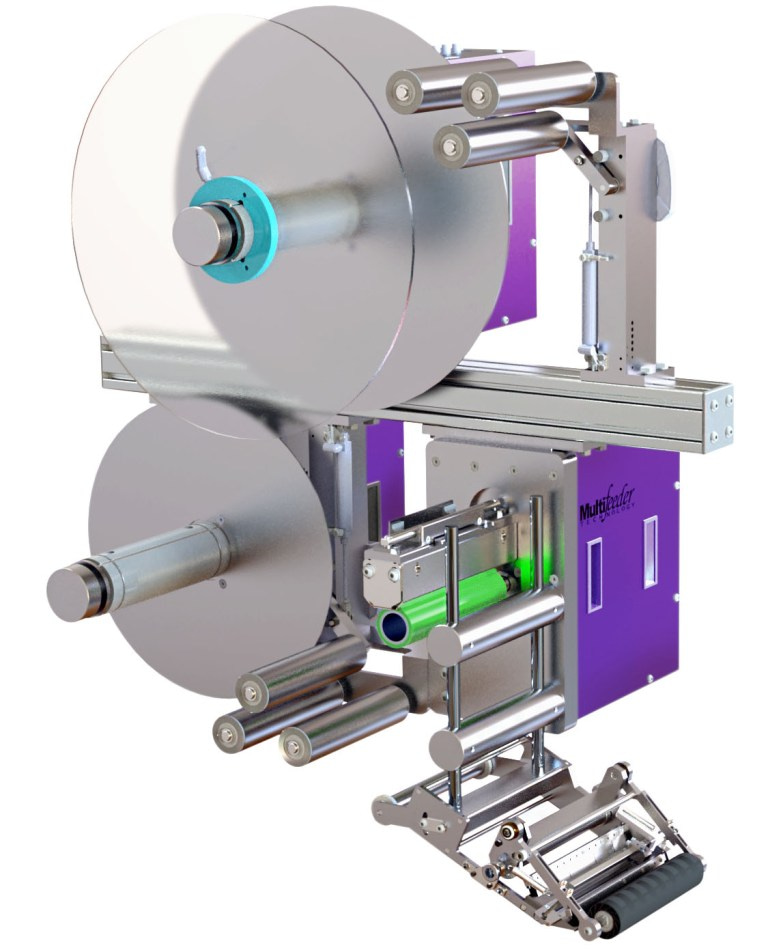

Tax Stamps

Best Recommended With A Track and Trace System for Tax Stamps

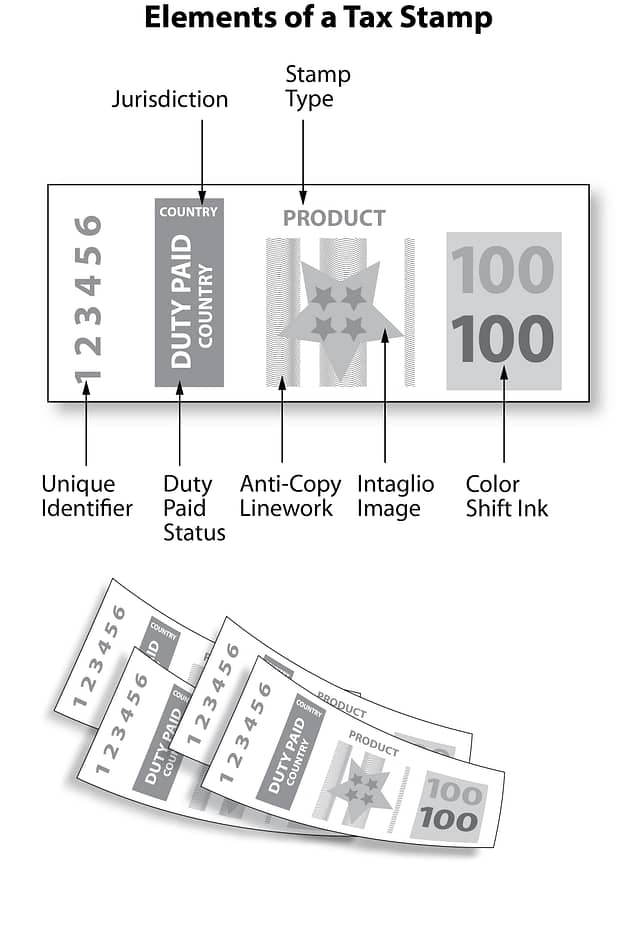

Tax Stamps are used to collect excise tax’s placed on consumer goods or for a controlled substance such as alchohol, cigarettes, tobacco, cannabis, drugs, medicines, playing cards and many other products. A tax stamp, similar to a postage stamp is affixed to the product confirming proof that payment from the manufacturer has been made to the United States Government. Affixing the stamp over the opening of a product also acts as a anti-tampering seal. Utilizing embedded unique identifying codes, tax stamps provide tax confirmation, security, and product authentication for consumers and retailers. This ensures that the product is not counterfeit. The product can be tracked using track and trace technology from its origin through the complete supply chain to the final destination, thereby proving the products legitimacy.

Track and Trace System use:

Tax stamps are printed using several different reproduction processes such as offset, intaglio, and inkjet printing. There are many different printing techniques, substrates and special inks involved. Embossing is a relief style technique widely used to give the design a characteristic look of authenticity and security. Most tax stamps use security papers with security fibres and dots with embedded data, codes or serial numbers within the printed design to utilize track and trace technology. The more the complexity of a tax stamp, the more security and serialization the stamp can offer. Tax stamps in the 21st century are modern security tools using the latest technologies such as embedded data, holograms, security inks, taggants, track and trace and more in the future.

For further information about your Tax Stamp production needs, give us a call at 651-407-3100.

Want to See How your Product Integrated

with our Machines?

We perform video demos for serious inquiries that are interested in receiving a video

demo showing how well our machines work with your product.

Pizza Trays

Best Recommended with a 300mm Wide Hygienic Washdown Feeder

Pizza trays are made from durable fluted corrugated cardboard construction that are food-safe and FDA approved for handling food products. Pizza trays are used as a base for the pizza in the packaging process, and are usually brown or white in color, with white being used for presentations. The trays are usually rectangular or round in shape, and their sizes range from 10” to 18” in diameter. They are designed to hold heavy food products such as a pizza or cake, and provide a moisture barrier between the food and box to absorb liquid and ensure freshness. Pizza trays are good for the environment, and are 100% recycleable.

HWD Friction feeder Use:

MFT’s Hygienic Washdown friction feeders are the perfect machines to help transport corrugated pizza trays in an automated industrial packaging environment. Our HWD feeders can dispense pizza trays, pizza labels, or slip sheets from the feeders magazine, or if high capacity is needed, the pizza trays can be automated from an Automatic Product Loader (APL). If your customer is requiring a demanding high production rate for pizza production, or your system is outdated and needs to be automated, then the MFT Hygienic Washdown Friction Feeder integrated with an Automatic Product Loader (APL) is the solution.

For further information about your Pizza Trays feeding production needs, give us a call at 651-407-3100.

Want to See How your Product Integrated

with our Machines?

We perform video demos for serious inquiries that are interested in receiving a video

demo showing how well our machines work with your product.