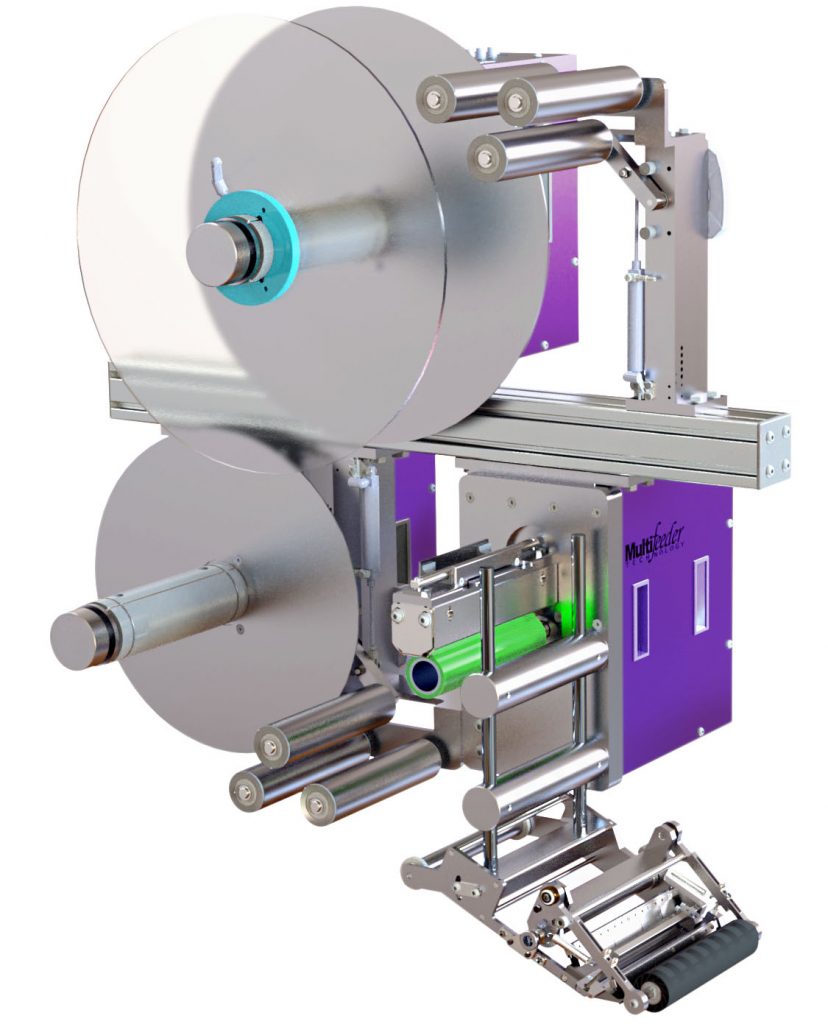

High Performance Commercial Product Labeling Machine

When you need high performance label application, the new and updated 103hsm+ is the labeler for your production line.

Now equipped with three independently powered, synchronized 3-axis servo drive motors for unwind, rewind, and drive. A brand new feature for the 103 is the Air Pel pneumatic actuators for precise micro tension control. Just like our other labelers the 103hsm+ is compact in design, versatile to handle up to a 20” diameter roll of labels 4” or 8” wide standard or maximum. The MFT 103hsm+ Label Machine offers the speed and accuracy required in today’s production environment.

Applications:

Adhere labels to packaging, cartons, sheets and more.

MFT 103hsm+ Typical Applications

- Scratch Off Labels and Cards

- Extended Content Labeling

- Direct Mail Tabbing

- Gap-less Magnet Application

- Box Labeling

- High Speed Web Press Labeling

- Game Piece Labels

- Food product labeling

- Bottle labeling

- And many more…

- Minimum product size: 10mm (W) x 10mm (L)

- Maximum product size 4 inch width*: 100mm (W) x 1000mm (L)

- Maximum product size 8 inch width*: 100mm (W) x 1000mm (L)

- Maximum speed:** 200 meters per minute

- Power requirements: 110/220V 50-60 hz 6A

- Operating temperature*: 0°-35°C (32° -95° F)

*All MFT Automation equipment can be designed to meet your specific production requirements. Please contact one of our experienced Application Engineers to discuss many solution options available to you.

** Subject to product review and configuration.

- Equipped with three independently powered synchronized 3-axis servo drive motors for unwind and rewind.

- Pel Air pneumatic actuators for micro-tension control.

- Flexible, stand-alone or integrate with existing production lines.

- Highly adaptable software package. Label detection and variable speed correction available with Accutipping.

- Compact design handles up to 20” diameter roll of labels, 4” or 8” wide standard or maximum.

- Modular 20” unwind/rewind label applicator with 12” wide Peel Plate.

- Stand

- Stack Light

- Low Label Detect

- Encoder with speed following Accutipping

- Dual Head Auto Switching

- Vacuum Takeaway

- Auto Splicing

Equipped with customizable computer controls with on-board panel for flexible controls. Software platform is flexible to run many different types of applications.

Remote control panel for easy control from the loading/operator side.