The coronavirus (COVID-19) has changed our way of life in 2020 — both personally and professionally. Employees are adapting to work from home policies. People are adding facemasks to their wardrobe. Companies are changing the way they do business. There’s a lot that’s changed.

For companies who manufacture and package medical supplies — we applaud you. These last six months have pushed you to adapt and accelerate production, helping millions of Americans stay safe. But the pandemic isn’t over yet. Hospitals across the U.S. are still struggling to keep people on the front lines safe. And, the need for PPE and COVID-19 medical supplies still remains a necessity.

Together, manufacturers and equipment providers can create more of these products. One of the first steps to doing this is to automate the packaging of PPE and medical products.

Boxes and Cartons for Automated PPE Packaging

- Facemasks

- Hand sanitizer

- Gloves

- Eye Protection/Gloves

COVID-19 Products for Automated Medical Packaging & PPE

- Test Strips (Automate packaging & batch counts)

- Test Kit Boxes and Cartons (Automate serialization & place UDIs)

- Disposable Thermometers (Automate packaging & batch counts)

- Manuals & Instructions

This blog is for those who already manufacture COVID-19 supplies, and those who want to start. If this sounds like something you’re interested, we’ve identified a few ways to help you jump in head first. If you’re already producing COVID PPE or supplies but need increased output, these apply to you as well.

How to expedite PPE & Medical Packaging Output

1. Use accurate serialization and UDI placement

“Serialization” and “unique device identification” aren’t foreign words to medical and pharmaceutical companies. These tools help safeguard products and track them throughout the entire supply chain. This is especially important for high demand products — like COVID PPE and medical supplies — that move fast. Automation equipment that supports serialization and UDI placement can help output acceleration. In turn, it could help provide medical facilities with more of the products they need during the pandemic.

2. Automate your batch counting and banding

During the pandemic, production line employees are (hopefully) following social distancing recommendations. Meaning, manual counting and preparation of products can take longer. This can cause some serious pains when your main goal is acceleration of product output. Automated equipment that batch counts and bands your products is a great solution. It offers limited human interaction and could offer some serious ROI right now.

3. Implement verification technologies into production

This step works hand-in-hand with step #1. Verification can be combined with serialization/UDI placement devices to create an airtight process for product traceability. Together they ensure the right product is being assigned the right code at the right time. Specific verification technologies that will help you accelerate your production include:

- Vision systems

- Barcode readers

- Rejection systems

Watch the video below to see some of these in action!

4. Invest in extra labeling machines and friction feeders

For obvious reasons, you’re likely experiencing high product demand. Hiring more employees, buying equipment, or upgrading existing equipment can help. But, we recommend focusing on options two and three.

Not sure if you need new equipment or can upgrade what you have? Talk with your automation equipment manufacturer or contact our team here.

A great place to start when evaluating equipment options is to start with what you have. Next, check your equipment’s cleaning and sanitizing options. With the pandemic still in full swing, there are regulations set by the CDC and FDA that must be upheld. To help meet these, we recommend looking into CIP automation equipment — also known as hygienic equipment. Below are a couple of hygienic options that could keep your company, products, and team safer.

Our PPE & Medical Packaging Equipment

Track & Trace System

for PPE & Medical Packaging

This system offers turnkey product handling for serialization coding, printing, inspection, and rejection. It also provides a trackable data file. Learn more about the Track & Trace system here or request a quote below.

Automatic Product Loader

for PPE & Medical Packaging

This machine multiples the product capacity of our MFT friction feeder systems by maximizing runtime and minimizing operators. Learn more about the Automatic Product Loader here or request a quote below.

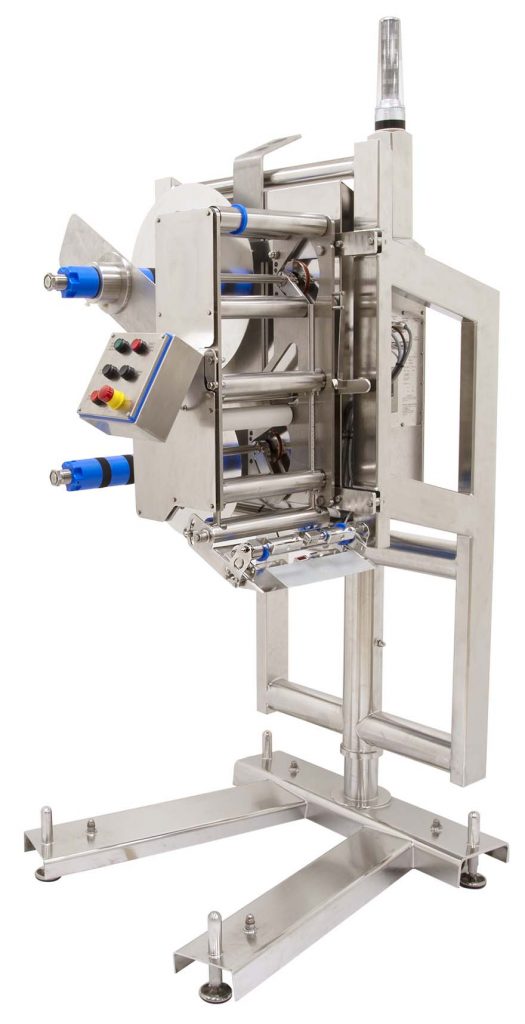

Hygienic Labeler

for PPE & Medical Packaging

The Hygienic Labeler 300 meets IP69K requirements and meets and exceeds IP66/NEMA4X standards. Its Clean-in-Place design also provides minimal contamination points. Learn more about the Hygienic Labeler here or request a quote below.

Hygienic Friction Feeder

for PPE & Medical Packaging

This feeder is available in the 300 and 600. Both meet sanitary requirements and comply with IP66 or higher standards and NEMA4X standards.