At Multifeeder Technology, our purpose is built upon 3 pillars: our proven process that we’ve spent years refining and perfecting, our incredibly talented team, and our constant drive for continuous improvement. These three strengths support the Multifeeder Technology Way; a method for creating high performance systems that stand out on production lines and an intention our entire team stands behind.

3 Techniques for Successful Automatic Label Application

If you’re looking to learn more about proven labeling techniques for automatic labeling and what’s needed for your label applicators, this blog is a great place to start. While there are many techniques in the industry, wipe-on labeling, tamp label applicators, and blow-on labels are three techniques we recommend for successful automatic labeling. Let’s dive into each technique with a bit more detail.

1. Wipe-on Label Applicator

Sometimes referred to as “merge” labeling; wipe-on labeling is where a label is dispensed in the same direction of flow as a product when a label is being applied. This is an automatic labeling technique that is widely used in the industry but requires precise set-up for optimal production speeds and quality output. It is also used for products with irregular shapes and surfaces that are not flat (source).

Wipe-on label applicators typically require the base product to be moving and consistently presented to the labeler. While the product moves towards the labeler, a free rotating roller or brush is used to aid the transfer of the label onto the moving product. From there an encoder can be used to track the speed of the product the label will be applied to so the labeler can apply accurately if the product speed might vary.

For this technique to be successful, your automatic labeler should have either a single axis or multiple axis motor. A single motor will assist with unwind, rewind, and drive; however, it will likely require clutching mechanisms for the unwind and rewind functionality. Whereas a multiple axis motor separately powers the unwind, rewind, and drive.

High-Speed Applications

For wipe-on labeling applications requiring higher speeds, a vacuum box or powered unwind may be implemented. (See the third technique to learn more about vacuum/blow boxes and blow-on labeling.) To meet these high-speed and tight accuracy requirements, a second stage may be added to the labeler such as:

Vacuum belt with motor drive: this option allows the label to be dispensed with the adhesive open (non-adhesive side facing the vacuum belt). The vacuum belt can then adjust position or speed to accurately apply the label such as using Multifeeder’s Accutipping controls.

Driven rotary vacuum wheel: this can transfer the label from the labeler to the product in a second stage for added speed or accuracy, similarly using servo controls such as Multifeeder’s Accutipping controls.

2. Tamp Label Applicator

A tamp applicator is a contactless technique for applying smaller labels on products. It is most commonly used on print and apply labelers; however, this technique can also be used on wipe-on label applicators for 3D products or hard-to-reach label placements (i.e. recessed areas). MFT 150pa Print and Apply Automatic Label Applicator

Tamp labelers place the label onto an air cylinder tamp pad or vacuum tamp pad before placing the label onto the product. As the product moves down the conveyor, a pressure sensor (such as Multifeeder design) can be used to indicate if the tamp pad comes into contact with the product. This is especially valuable for variable height products or more intricate products. Such products may also benefit from a complex tamp pad that can place a corner label on more than one surface.

To support a complex tamp pad, a second air cylinder or a hinge (spring-loaded or gas shock) may be required for the second side. A pneumatic style smart tamp or heavy-duty smart tamp could also be used to prevent any tweaking or sensitivity to dirt; learn more about the smart tamp we use in the MFT 150pa Print and Apply Automatic Label Applicator. Additionally, a tamp pad may feature vacuum to hold the label while an airblast is used to release the label onto the product.

3. Blow-on Label Applicator

This sophisticated technique is sometimes used to replace the industry-favorite wipe-on labeling; although it is slightly less precise. Blow-on label applicators use a controlled blast of compressed air to place labels at high application rates. (source 1, source 2). This technique is commonly used for blow labels on coupons and other high-speed applications that require a contactless application (i.e. glass or other fragile products).

A blow box or vacuum box can be used in a similar way when paired with a wipe-on labeler. Oftentimes the vacuum/blow box uses a muffin fan to create a vacuum effect by holding the label to the bottom surface of the transfer device. The wipe-on labeler will index the label onto the bottom surface of the vacuum/blow box, which is then held in place by vacuum. When a product traveling below the box gets to the location the label is to be applied, an air blast releases the label onto the product below. This feature allows the labeler to be placed either in-line or perpendicular to the base product flow depending on label orientation requirements.

Defining which automatic labeling technique is best for your product or application can depend on a series of variables. If you’re interested in learning more about these techniques and other labeling solutions for your product, we’re happy to help. Get in touch with one of our automation and labeling experts by contacting us here or check out some of our labelers here.

Send samples of your labels and base product to us for a complimentary evaluation and test video. Click the button below to get started.

Tags: Labelers, Integrated Systems

5 Things You Need For Successful Cannabis Labeling in 2021

The cannabis industry is a multi-billion dollar industry that has no intention of slowing down. It’s estimated that by 2022, the legal-marijuana industry could impact the economy by $77 billion (source). If you’re in the business of cannabis production, you’ll inherently need to think about the role packaging plays in your process. With packaging comes the need for cannabis labeling and safety protocols. This blog shares a few of the steps, products, and equipment worth trying for cannabis labeling. Above all, we hope one of these steps helps you to have a blooming business in 2021.

1. Identify a Concentrate Container

First, you’ll need something to contain your cannabis. For concentrated versions of the plant, cartridges and containers are common options. Versions of these concentrate packaging may include glass concentrate containers, vape cartridges, oil cartridges, AVD cartridges, and Ccell cartridges. However, there are many options for this step.

First, you’ll need something to contain your cannabis. For concentrated versions of the plant, cartridges and containers are common options. Versions of these concentrate packaging may include glass concentrate containers, vape cartridges, oil cartridges, AVD cartridges, and Ccell cartridges. However, there are many options for this step.

2. Choose a Packaging Method

Secondly, you’ll want a way to transport and seal the container. To do this, you’ll need to figure out a plan for your packaging. A few commonly used products for packaging include flattened cartons, product free pouches (like a mylar bag), and round containers (similar to a pill bottle), or cartridge blister packaging.

3. Invest in Tamper Evident Labels or Stickers

Thirdly, you’ll want to seal your concentrate containers and packaging properly. You can do this by applying a tamper evidence dispensary label or a paper sticker label to the product and/or package. These small labels help protect the integrity of your product. By utilizing tamper evident labels or stickers, you’ll ensure your customers, product, and company are safe from anything harmful.

4. Select a Packaging Labeler

Finding a label machine that can properly place your dispensary labels is key to producing more products, selling more products, and keeping your brand standards in place. When searching for a cannabis label applicator it’s important to know if you can feed your packaging through the labeler with ease and precision. Doing a FAT or Factory Acceptance Test will help you confirm this and ensure the performance is up to par. This also ensures you’re investing in a packaging labeler that actually works for your product.

Oftentimes the label applicator will place the tamper evident labels or stickers on the product for you automatically — saving you time and money. When pairing the labeler with a feeder system, you’ll ensure your cannabis production is fully automated and secure. There are even hygienic labelers and hygienic feeders if you’re looking to keep your space clean and sterile.

5. Know your State’s Cannabis Labeling Laws

Finally, if you haven’t already educated yourself on the labeling laws in your state now is the time. Below are a few labeling laws for states that have legalized cannabis — more cannabis state laws can be found here (Note: Always refer to your state’s government website for updated cannabis laws).

-

- Alaska Cannabis Labeling Laws

- California Cannabis Labeling Laws

- Colorado Cannabis Labeling Laws

- Illinois Cannabis Labeling Laws

- Michigan Cannabis Labeling Laws

- Maine Cannabis Labeling Laws

- Massachusetts Cannabis Labeling Laws

- Nevada Cannabis Labeling Laws

- Oregon Cannabis Labeling Laws

- Vermont Cannabis Labeling Laws

- Washington Cannabis Labeling Laws

In conclusion, as the cannabis industry continues to flourish, so will the equipment and packaging options. If you’re wanting to increase output, improve your packaging standards, or update your cannabis production line — we have a solution that can help. Check out some of our labelers, friction feeders, and integrated systems or get in touch with us below and someone from our team will be in touch.

DISCLAIMER: The contents of the Multifeeder Technology website regulatory pages are for general information only. The information herein should not be relied upon for legal advice on state marijuana laws. We provide links to state cannabis regulatory sites; we do not vouch for or assume any responsibility for the content, accuracy or completeness of material presented in linked sites. The information presented on these pages may not reflect the most current legal developments in the marijuana industry. We disclaim all liability in respect to actions taken or not taken based on any or all of the contents of this site to the fullest extent permitted by law.

Join Us at PACK EXPO Connects

Recently, PACK EXPO announced they will cancel their traditional trade show format for a brand new digital experience. This digital conference is called Pack Expo Connects 2020 and occurs from November 9-13, 2020.

Multifeeder Technology will feature two automation systems at the event: the Hygienic Washdown System and the Booklet to Web Tipping System. These two systems will have a series of live demos scheduled throughout the event that attendees can watch and ask questions via a live chat. The times for these live demos are below:

-

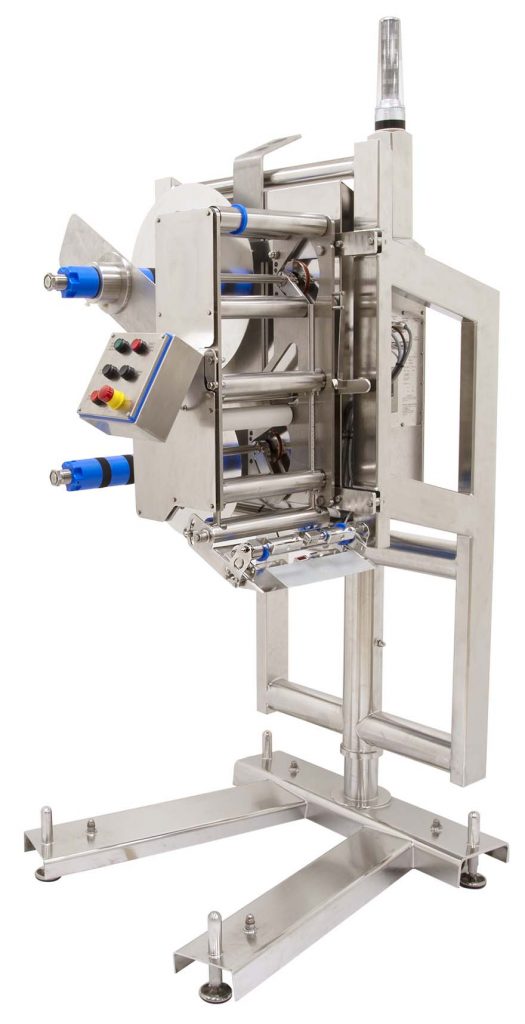

- Hygienic Washdown System (Labeler & Friction Feeder) — Designed for food-grade applications and optimal cleaning.

- Mon, November 9 – 10:00 AM – 10:15 AM (CST)

- Tue, November 10 – 10:00 AM – 10:15 AM (CST)

- Wed, November 11 – 10:00 AM – 10:15 AM (CST)

- Thu, November 12 – 10:00 AM – 10:15 AM (CST)

- Booklet to Web Tipping System — Effortlessly apply tip-on product to a web at production speeds.

- Mon, November 9 – 11:00 AM – 11:15 AM (CST)

- Tue, November 10 – 11:00 AM – 11:15 AM (CST)

- Wed, November 11 – 11:00 AM – 11:15 AM (CST)

- Thu, November 12 – 11:00 AM – 11:15 AM (CST)

- Hygienic Washdown System (Labeler & Friction Feeder) — Designed for food-grade applications and optimal cleaning.

Learn More about the Hygienic Washdown System

This system is designed with two machines: the hygienic labeler and the hygienic friction feeder (in a 300 or 600 size). The MFT Hygienic Feeder and Labeler system was designed for food packaging, clean room, and medical device applications. It features a clean-in-place design that meets IP69K and NEMA4X standards. In the video below, we feature the MFT Hygienic Feeder & Labeler System placing and labeling corrugated pizza circles with accuracy and speed.

Learn More about the Booklet to Web Tipping System

This system features a lugged driven discharge with lead edge registration to help it repeatedly place products in the same spot. In the video below we pair our Booklet to Web System with a 103hsm+ Label Applicator to run extended content labels.

Connect with us at PACK EXPO Connects

There’s a few ways you can get in touch with us at PACK EXPO Connects.

- Attend one of our demos!

- Add the Multifeeder Virtual Showroom to your show planner

- Add one of our products to your show planner

- Start a live chat with someone from our team

- Request a private meeting with someone from our team to discuss your application or project

The following team members will be available to chat live with you during the demo sessions. Some may also be available for one on one meetings!

- Peter Nordling, General Manager

- Jim Iler, Regional Applications Manager

- Micah Collins, Applications Specialist

How to Automate UDI barcodes for Pharmaceutical Packaging

Automation has the ability to quickly introduce and expand life-saving products into society. However, some companies are faced with strict regulations while producing these products safely, efficiently, and accurately. One way pharmaceutical packaging companies combat this feat is by utilizing automation to apply UDI barcodes or Unique Device Identification codes on products.

What are the UDI labeling requirements?

The UDI labeling requirements align with the Unique Device Identification System, which was signed into law in 2007. The system ensures unique identifier or codes are assigned to medical devices manufactured across the globe (source). Pharmaceutical labeling requirements mandated by the FDA, state the following:

“The Unique Device Identification System final rule (UDI Rule) requires device labelers (typically, the manufacturer) to:

-

- Include a unique device identifier (UDI) on device labels and packages, except where the rule provides for an exception or alternative.

- If a device is intended for more than one use and intended to be reprocessed before each use, the device labeler must also mark the UDI directly on the device.

- Submit device information to the Global Unique Device Identification Database (GUDID).”

- Include a unique device identifier (UDI) on device labels and packages, except where the rule provides for an exception or alternative.

Successful companies automate their pharmaceutical labeling process with product feeding, labeling, and verification systems equipped for UDI barcodes. These types of automation equipment can also typically feed products like Tyvek lids, die cut cartons, foil pouches, clear bags, and more.

How to Automate UDI Pharmaceutical Labeling

When applying a UDI code, it is possible to apply a label or to print the code directly onto the products. The products are loaded into a MFT Automation Friction Feeder that will gently feed the product one at a time, and transfer them one at a time onto the discharge of the feeder. The UDI codes are then applied onto the products automatically as they travel on the discharge of the feeder. After the UDI code has been applied to the product, a vision camera system is utilized to confirm the identification has been properly placed on the product. This process is also known as serialization.

What is serialization?

Serialization is the process of applying a unique code to each individual product. It provides a system to track and trace a pharmaceutical product from its original source through the entire supply chain.

Using serialization technologies for pharmaceutical packaging is a great way to safeguard products. Automated quality management systems (QMS) can also help you save time and money on packaging production. These types of automated technologies help companies remain competitive — especially in highly regulated industries like the pharma industry.

MFT Automation manufactures friction feeding, printing, and labeling machines for Fortune 500 pharmaceutical companies. These machines can print, apply, and label UDI codes onto products automatically. They can also integrate with Ink Jet and Thermal transfer print systems, to keep pharmaceutical packaging lines performing at optimal speeds. If you have a unique carton or product that needs feeding or labeling within the pharmaceutical packaging industry, our customized solutions can help.

Get in touch with us below and start saving time, money, and labor with automated Unique Device Identification and pharmaceutical labeling.

How to Choose a Labeling Machine for Food Packaging

Did you know the Global Foods Packaging industry could reach $400 billion by the year 2025? While this industry continues to grow, so does the need for companies to automate their manufacturing processes. This is where automation equipment can be a resource; such as labeling machines and label applicators.

If you work in engineering or operations, you may be looking to improve your process. If you’re a business owner or purchasing manager, you need a labeler that will justify the investment. No matter what seat you’re in, there are a few steps to take before choosing a labeler machine.

Step 1: Define Production Challenges & Goals

Before you begin researching automatic label machines, take time to define what it is you’re trying to fix. Knowing this up front will help you decide on a label machine and manufacturing partner.

Have you tried to implement automation equipment but felt resistance from your team? In this case you may need an automation equipment manufacturer who provides on-site training. Have you launched a new product and need automate a difficult packing process? In this case, you might need a customized integrated labeling system. Were you recently hired to help improve production timelines and output? Are you tasked with implementing new technology and strategies on the production line? In these situations, you might need an automation equipment and a manufacturer who has a process that’s supported by data and procedures.

Here are some questions to help you understand your situation, challenges, and goals.

Questions to Ask

-

- What is the smallest and largest product that needs a label applied?

- What size labels do I need?

- How fast and how accurate do I need to apply the labels?

- What production issues is our team currently experiencing?

- What does successful automation look like to my customers, team, and company?

Step 2: Research and Select a Label Manufacturer

Choosing an automation partner is like finding a dealership before you can test drive your new ride. Factors like the location of the dealership and number of vehicles to choose from are important. But the “feel-good” factors like your connection with the salesman or their Google reviews are also important.

The same goes for choosing a label manufacturer and partner for your automation equipment. They need to have equipment that can do what you need it to do — like apply labels accurately and efficiently. And, they need to offer the customization and support your team and application need. Below are a few questions you can ask yourself and manufacturers when vetting out new partnerships. Be sure to also get a feel for their company and culture as well.

Questions to Ask

-

- Does the manufacturer have proof of experience with my application (i.e. YouTube videos)?

- What kind of aftermarket support does my team need? Does the manufacturer offer this?

- Are there testimonials that showcase the manufacturer’s work with other food packaging companies?

- Does the manufacturer offer free video trials of our products processed on their equipment?

- Do they manufacture their own equipment in-house? Or, do they purchase and resell equipment from overseas suppliers?

Step 3: Identify Your Label Applicator Needs

Sometimes you aren’t sure what type of labeling machine or label applicator you need (example pre-printed or print and apply) — and that’s okay. Your manufacturing partner should be able to help identify the best solution based on the challenges and goals you share.

When operating in a food manufacturing environment, a good place to start is to consider the type of labeling machine you need. There are two basic types of food labeling machines: a hygienic labeler or a standard labeler. Both are great options depending on the level of regulations required on your production lines — like ones permitted by the FDA.

Due to rising foodborne outbreaks and recent CDC and FDA regulations, companies are opting for automation equipment that can be heavily sanitized. The best labelers for this type of cleaning are typically hygienic labelers. If your equipment doesn’t come into contact with food or beverages or isn’t even in the same facility, you may be okay utilizing a standard labeler.

Be sure to discuss these concerns and any types of regulations and requirements your company must follow with your manufacturer. It’s worth the time and research — especially when it can prevent you from having to shut down your production line.

Questions to Ask

-

- What type of automatic label machine do I need to follow our company’s food and beverage regulations?

- Are the parts for the label applicator manufactured in-house or purchased?

- Is the food labeling machine customizable?

- How often does the labeler machine need cleaning? What types of cleaning agents do we need to use?

Step 4: Test your samples on the Labeling Machine

It never hurts to ask. A manufacturer who is confident in their products being able to solve your needs and providing a customized experience will say yes. And there’s not a better way to validate your decision before buying something, than to see it in action.

So, ask to send samples of your product to the manufacturer and either watch the labeling machine in person or request a video of the test. This gives you an opportunity to ask questions and ensure the machine produces a quality product you’re proud of.

Questions to Ask

-

- Does the labeling machine perform at the speed that our production process needs?

- Does the automatic label machine apply labels accurately at this speed?

- Will there be future testing after purchasing the labeling machine but before shipment? NOTE: This may include Factory Acceptance Test (FAT) or Site Acceptance Test (SAT).

Step 5: Confirm Lead Time Specifics

Last, but not least, get clarification on the implementation process and lead time. There’s nothing worse than investing in automation equipment that takes months to produce any results and ROI. Be sure to get clarity on timelines and expectations from your manufacturer. You’ll be thankful to have a plan in place with a process and partner you trust.

Questions to Ask

-

- How long will it take to implement?

- What types of training are available?

- Do you offer start up help and training?

- How long is the warranty on the labeling machine?

- What technical service support is available if questions or concerns arise?

But the most important question to ask yourself after researching, requesting quotes, and vetting your options is…

“Do the labeling machine and label manufacturer I’m considering support the challenges and goals identified in step one?”

If your answer is no, it’s time to start the process over. If you’ve tried this process and are still struggling to find a label applicator that meets your needs, we’re here to help. Get in touch with us by requesting information on our automation solutions below.

How To Clean Label Applicator Machines

MFT 150pa Labeler

General Information:

The MFT 150pa is simply the best print and apply solution for your production needs. If your need is to integrate a labeler into an existing production line or combine it with a flexible feeder or conveyor system, our MFT 150pa is the labeler you need, along with our feeder and other components. The MFT 150pa’s design is operator friendly, built to last, and adaptable to your future production requirements.

MFT 150pa Typical Applications

- Credit card labeling

- Pharmaceutical labeling

- Bar coding applications

- UPC over labeling

- Food and beverage labeling

- irregular product application

- Integration with MFT friction feeders

- Combined with an MFT conveyor for mobile production line

- And many more…

- Maximum media width: 133mm [5.25″]

- Minimum media width: 25.4mm [1″]

- Minimum media length: 6.3mm [0.25″]

- Maximum media roll size: 308mm [12″ O.D.], 76mm [3″ I.D.]

- Maximum dispense speed: 12 inches per second

- Placement accuracy: up to +/- 1mm

- 6 inch non-rotating small profile cylinder

- Heavy duty “Smart Switch”

- Quick disconnect label pad

- 12 inch media unwind

- Easy to use HMI

- Designed to fit where needed

- Easy to learn open thread pattern and operation

- Ready inputs and outputs for system integration

- T-Base style stand with low toe feature

- Straddle style stand

- Remote mountable three color alert light

- Wide web print engine

- Left handed model

- Longer stroke cylinder

- Additional quick change label pads