The food packaging industry requires your operation to adjust to rapidly evolving trends and regulations, which are often driven by shifting consumer preferences for convenience and sustainability. It is also imperative that your facilities ensure a consistently sanitary environment. To keep pace, it is important to embrace automation that enhances efficiency, meets strict sanitation standards, and adapts to ever-changing production needs. At MFT Automation, we specialize in flexible automation solutions designed to streamline food packaging and optimize your production processes.

Why Flexibility is Key in Food Packaging Automation

Food production presents unique challenges: from handling different packaging formats to maintaining hygiene and compliance. Our flexible automation systems allow you as a food manufacturer to:

- Increase Efficiency – Automated equipment in our washdown and hygienic line reduces manual labor, speeds up processes, and enhances overall productivity.

- Maintain Sanitation Standards – Equipment built with passivated stainless steel and FDA-approved contact surfaces ensures compliance with food safety regulations.

- Adapt to Market Demands – As consumer preferences shift, automation must support new packaging types, sustainable initiatives, and materials like wax paper, cardboard, and biodegradable plastics.

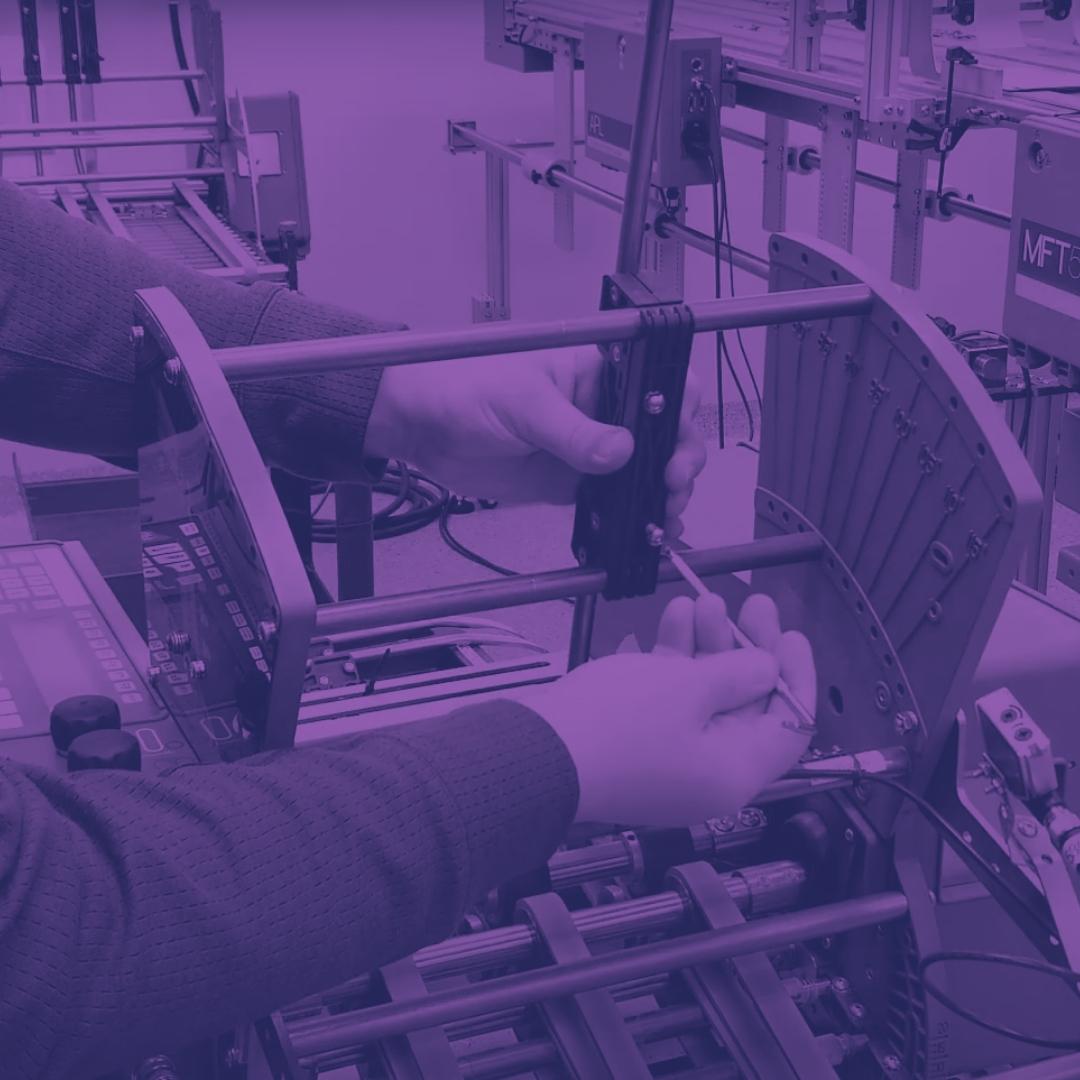

Hygienic Washdown Friction Feeders: Solutions for High-Performance Food Packaging

Designed for food producers who require reliable, washdown-ready automation, our Hygienic Washdown Friction Feeders ensure seamless food packaging with:

- Minimal Contamination Points – Reduces downtime with a design that minimizes the need for disassembly and reassembly.

- Easy Cleaning & Maintenance – Built with 304 passivated stainless steel, offering superior resistance to moisture and corrosion.

- Sanitary Compliance – FDA-approved contact surfaces including feed belts, stripper wheels and discharge belts, and IP-certified components allow you to meet industry regulations.

Whether utilizing flow wrapping machines for snack packaging or food production machines for frozen goods, MFT’s custom automation solutions provide the flexibility you need to stay competitive.

Future-Proof Your Food Production with MFT Automation

Your food industry operation demands scalable, hygienic, and efficient automation to keep up with rising production needs. MFT Automation’s custom food packaging machines empower manufacturers to increase output, maintain safety standards, and adapt to evolving industry trends.

Ready to optimize your food packaging process? Contact MFT Automation today to discover how our solutions can enhance your production line.