Vertical form fill and seal (VFFS) machines have become essential for companies packaging food, medical supplies, and pharmaceuticals. As demand grows for safer products, faster throughput, and more flexible packaging formats, manufacturers are expanding their VFFS operations with supporting automation that keeps lines running smoothly.

At MFT Automation, we play a critical role in strengthening the systems that surround automated VFFS lines. From hygienic friction feeders and labeling systems to robotic pick-and-place solutions, tray forming, sanitary conveying, and custom solutions, we’ll help you engineer a fully integrated packaging line that scales with your production goals.

If you’re looking to improve efficiency, increase product safety, or automate more of your packaging process, the right automation partner can make all the difference.

The Role of Vertical Form Fill and Seal Machines in Modern Production

Vertical form fill and seal machines streamline three critical packaging steps: forming the pouch, filling it with product, and sealing it for distribution. Their speed, flexibility, and compact footprint make them ideal for industries prioritizing product safety, hygiene, and throughput.

As packaging demands evolve, facilities rely on VFFS systems to handle:

- More frequent product or SKU changeovers

- Variable pouch formats

- Stricter quality and traceability standards

- Higher output without expanding floor space

Because VFFS machines sit at the heart of high-volume operations, the systems surrounding them must perform with equal precision. That’s where integrated automation becomes a strategic advantage.

Why Integrated Automation Matters for VFFS Lines

To get the most out of your VFFS equipment, the machinery upstream and downstream must work in harmony. Supporting automation helps you:

- Improve throughput by eliminating manual bottlenecks

- Ensure hygienic handling for food, medical, and pharma packaging

- Increase accuracy and repeatability for labeling, loading, and product movement

- Reduce changeover time with smarter, modular equipment

- Create end-to-end traceability with labeling and verification systems

MFT Automation specializes in these surrounding components–the systems that enhance VFFS performance, strengthen compliance, and expand automation across your line.

Supporting Automation Systems That Strengthen VFFS Performance

This is where MFT delivers the most impact. Whether you’re automating a single step or building a comprehensive packaging line, our systems help VFFS machines operate at peak efficiency.

1. Hygienic and Industrial Friction Feeders

Friction feeders are essential for adding inserts, coupons, cards, labels, or specialty materials into a VFFS workflow. In food, pharmaceutical, and medical environments, hygienic engineering is non-negotiable–and that’s where our Hygienic Washdown Series stands out.

These feeders meet IP67 or higher and NEMA4X standards and are built with:

- Type 304 stainless steel

- 1200-watt brushless servo motor

- An open, self-draining design

- FDA-compliant materials with no hollow areas

Their clean-in-place (CIP) compatibility minimizes contamination risk while keeping your line fast, compliant, and easy to maintain.

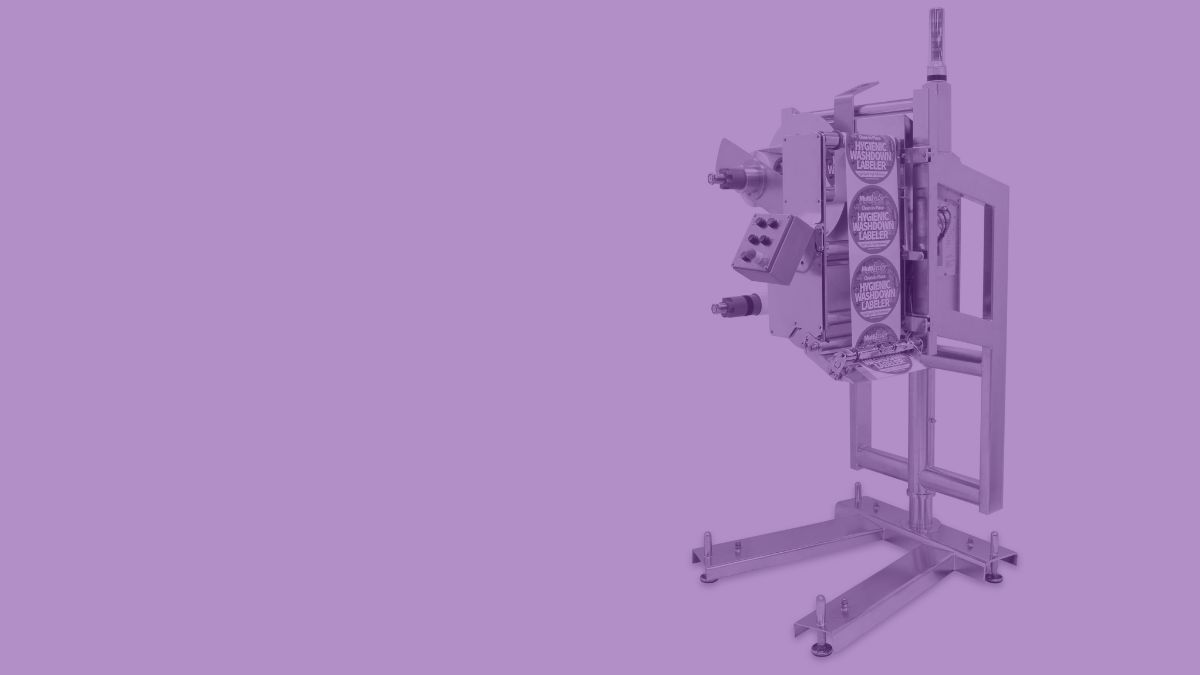

2. Hygienic Labeling Systems

A VFFS line is only as accurate as its labeling and identification. For food, pharma, and medical packaging, hygienic labelers allow you to maintain compliance without downtime.

MFT’s hygienic label machine features:

- Open, self-draining construction

- Moisture and corrosion resistance

- Minimal disassembly for quick sanitation

- High-precision servo control for consistent placement

These product labeling machines integrate easily into automated packaging equipment to support traceability, coding, and regulatory requirements.

3. Robotic Pick-and-Place and Loading

Robotics are increasingly important in VFFS operations, especially for:

- Loading trays or containers

- Transferring flexible or semi-rigid packs

- Sorting, stacking, or orienting products

- Supporting sanitary or clean-room workflows

As a Diamond Partner with Mitsubishi Electric Automation, MFT offers robots in ISO3 clean room, IP20, IP65, food-grade, and chemical-resistant versions. Robotic flexibility allows you to boost accuracy, speed, and safety while automating the “fill” and “transition” steps around VFFS equipment.

4. Tray Forming for Container-Based VFFS Applications

While many teams think of VFFS exclusively for bags and pouches, a growing number of operations are integrating tray forming into their packaging lineup. The MFT Tray Former 500 supports this by forming consistent trays at high speed with:

- Toolless die and ram changeovers

- Drawer-style access for easy maintenance

- A compact footprint for tight floors

- Simple operator controls

- Servo-driven precision and welded steel stability

As part of a VFFS ecosystem, the tray former delivers reliable container forming for packaging filled trays, cups, portion packs, or semi-rigid formats.

5. Conveying and Material Handling

Reliable product flow is critical for VFFS performance. MFT conveyors, including washdown-ready options, help you move materials safely and consistently through forming, filling, sealing, labeling, and packing stages.

This includes:

- Hygienic conveyors for food and pharma

- Product transport between VFFS and downstream modules

- Support for automated inspection and rejection stations

- Space-conscious configurations for tight production areas

With sanitary construction and modular flexibility, your conveying system becomes an extension of your quality control strategy.

Why MFT Automation Makes an Ideal Partner for VFFS Lines

Your VFFS machine can only perform as well as the systems that surrounds it. That’s where MFT’s engineering-driven approach adds long-term value. When you collaborate with MFT, you get:

A Production Problem-Solver, Not Just a Component Vendor

We don’t just sell modules and widgets; we help you engineer a complete solution that solves real operational challenges.

Deep Expertise in Food, Medical, and Pharma Packaging

From hygienic design to washdown-friendly materials, our systems meet the standards these industries demand.

Configurable Systems That Scale with You

As you expand your VFFS operations, every MFT system is designed to evolve with your line and adapt to changing requirements.

Reliable Automation Backed by Quality Engineering

Every machine is built for long-term performance, operator-friendly usability, and minimal maintenance.

Stronger, Smarter, More Complete Packaging Lines

VFFS machines are foundational to high-speed packaging, and they’re even more powerful with the right automation partner beside them. Whether you’re improving an existing line or building a new one, MFT Automation supports you with hygienic equipment, robotic integration, tray forming, labeling, feeding, and connected material handling systems.

If you’re looking to elevate efficiency, expand automation, or solve a persistent production challenge, we’re here to help.

Talk with an Automation Specialist

Ready to strengthen your vertical form fill and seal operations?

Our engineering team is here to help you solve your next automation challenge and build a smarter, more scalable packaging line.