What is a Friction Feeder? And Other Frequently Asked Questions

Many companies have seen the benefits of automating their processes. Friction feeders are a powerful piece of automation equipment, capable of enhancing a system or boosting productivity as a standalone piece of equipment. Just learning about automation or friction feeders? As automation and friction feeder experts we have all the frequently asked questions answered!

Friction feeders are a powerful piece of automation equipment that separates and dispenses flat products from a vertical stack, one product at a time.

How does a friction feeder work?

Where are friction feeders used?

As a piece of automation equipment, friction feeders are often used in larger automation systems, though they can stand independently. Friction feeders can be found in several different industries including, packaging, printing, food, medical, and more. Examples of friction-feeding applications include tipping, batching, counting, inserting, collating, and more.

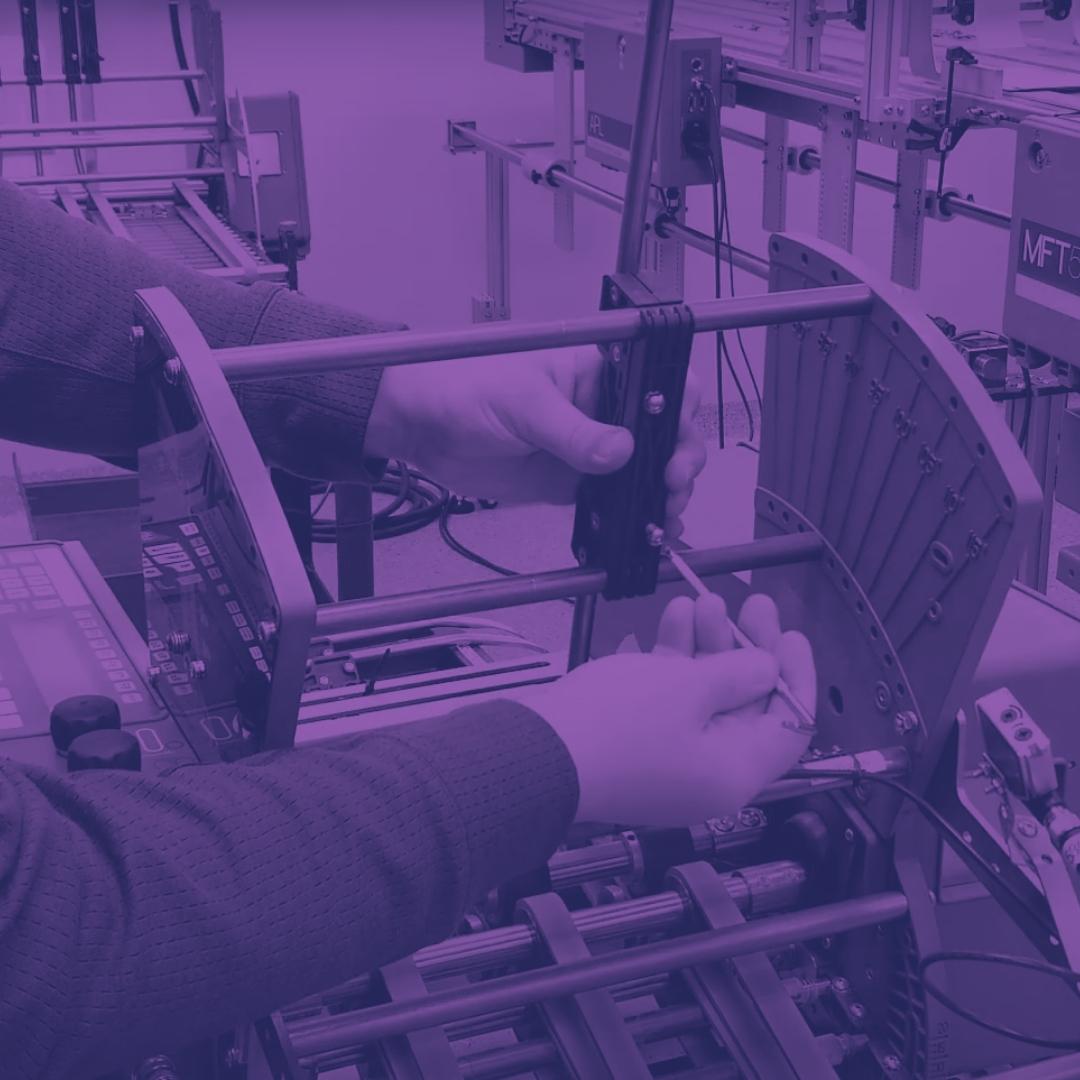

The best way to know if your product will feed is to test the product. At MFT Automation, we understand the need to test before you invest. If you send us a sample of your product we will send you a free video demo of your product being run through our equipment.

Why invest in a friction feeder?

Automation has a high return on investment. Time is money and companies save a lot of time when they invest in automation. Workers can focus on more complex tasks while the friction feeder takes care of tedious and monotonous tasks. These complex tasks are a more efficient use of wages when automation is an option. Product quality is also increased as friction feeders are more accurate and precise with placements and counting. Friction feeders are highly versatile in size, material, and maximum speeds to fit into any production environment and can easily be integrated into existing production lines or stand independently

What are the friction feeder options at MFT Automation?

Check out our high-performance friction feeders:

The Signature Series (v3)

A Different Angle: Versatile Vertical Friction Feeding

Generally, most friction feeders are placed above a transport, such as a lugged or vacuum belt conveyor, and dispense the product onto the surface at a straight or slightly downward angle. But some applications require a different angle.

Vertical feeding is a common solution for inserting a product into an opening on the top of various forms of packaging.

How to Install Feeder Parts After Unboxing Your ip3 Friction Feeder

To keep shipping economical, friction feeders are shipped partially assembled. Learn how to install feeder parts and components after unboxing your ip3 Friction Feeder.