A Different Angle: Versatile Vertical Friction Feeding

Generally, most friction feeders are placed above a transport, such as a lugged or vacuum belt conveyor, and dispense the product onto the surface at a straight or slightly downward angle. But some applications require a different angle.

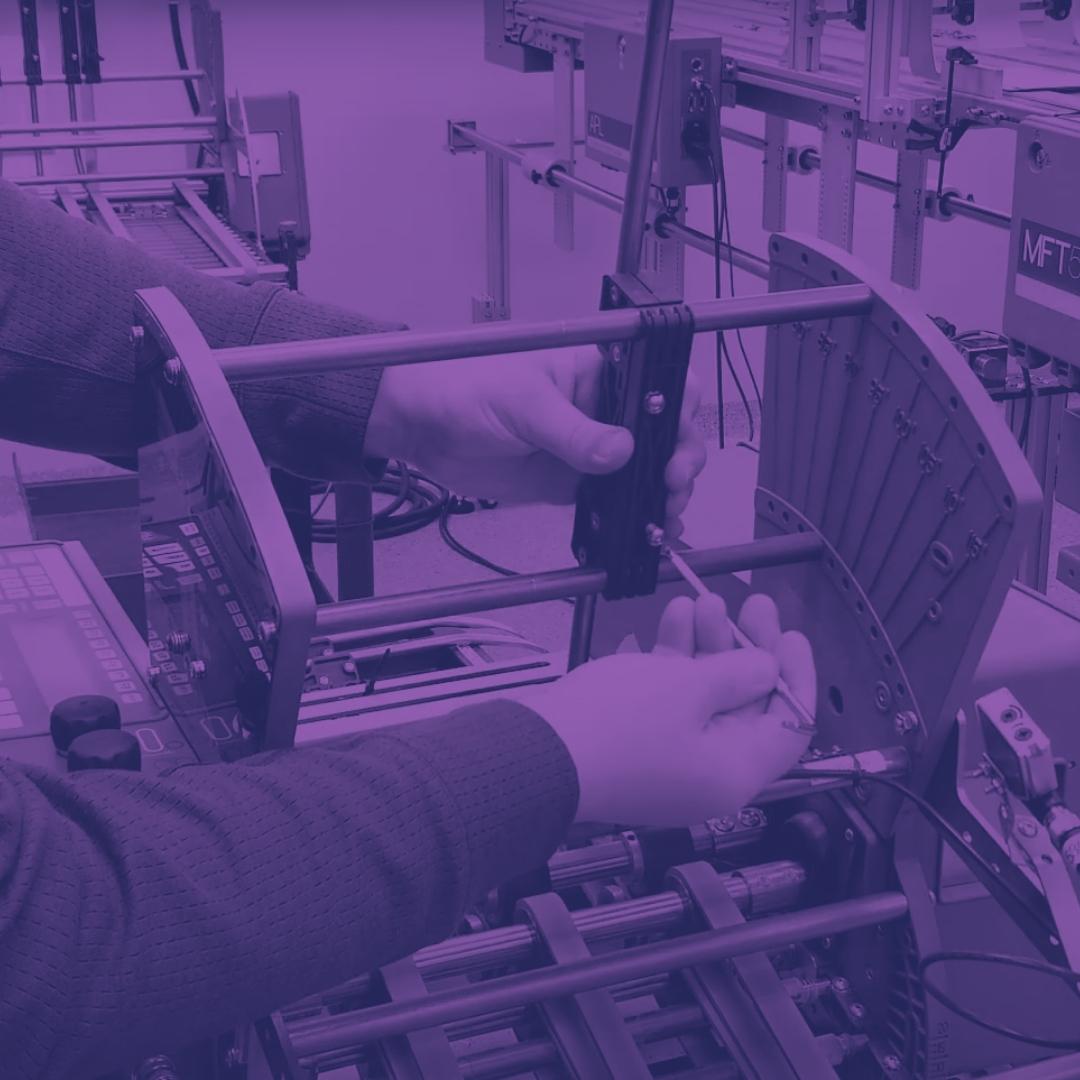

Vertical feeding is a common solution for inserting a product into an opening on the top of various forms of packaging.

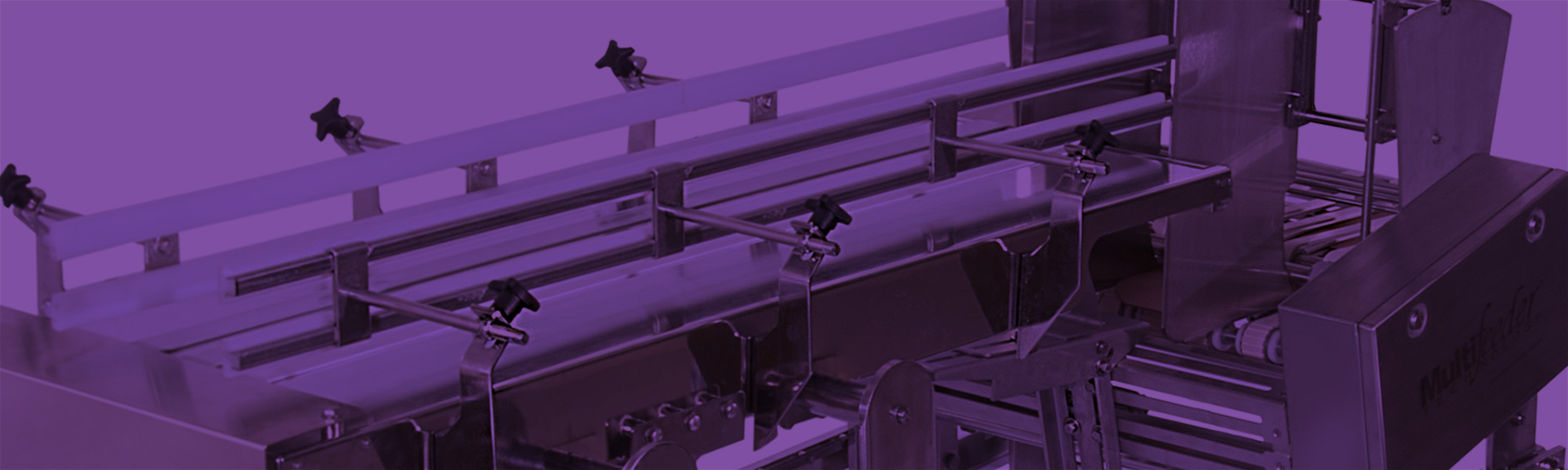

How to Install Feeder Parts After Unboxing Your ip3 Friction Feeder

To keep shipping economical, friction feeders are shipped partially assembled. Learn how to install feeder parts and components after unboxing your ip3 Friction Feeder.