Separating Stacks of Food Products

The MFT Automated Food Interleaver places sheets of paper, film, or foil under food products (underleaving), including burgers patties, deli meat, bacon, tortillas, cookies, pasta, and other food products. The sheets of material prevent the stacked food products from sticking together in their packaging. The Food Interleaver features a high-speed blade that cuts material precisely before it is delivered onto the conveyor belt, intersecting with the food product traveling on the conveyor. The Automated Food Interleaver can run two rolls of material for two lines of products and double the productivity. Compact and designed to integrate into existing production lines or new production lines seamlessly. Featuring a Washdown design, the MFT Automated Food Interleaver can be washed with harsh chemicals and water without compromising the internal components. It is ideal for sanitary environments, such as food packaging, where the equipment must be consistently and aggressively cleaned.

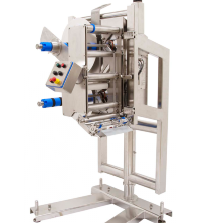

Hygienic Washdown Friction Feeder 600

Automated Food Interleaver

Our systems are highly customizable to match your application. Submit your current automation challenge and we’ll work with you to create a system that fits your specific needs.

PRODUCT VIDEO

Our Washdown and Hygienic Washdown line of equipment has tons of applications. See our food packaging equipment in action!

Want to see how your product feeds? Request a video demo and send us a sample of your product.

COMMON APPLICATIONS

Below are a few examples of common applications used with the Automated Food Interleaver. Our

machines all have a wide variety of applications, so please reach out if you have a question

regarding your specific application and we will find the right solution for you!

Looking for spare parts?

Current customers get access to our online store, the Parts Portal, for convenient and fast online ordering of spare parts and accessories.