Creating Access to the Base Product while Maintaining Control

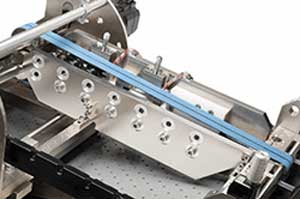

The Split Discharge is a customizable discharge option for MFT Automation’s Friction Feeder Families. The Split Discharge features an opening in the top of the discharges elastic belts that allow access to the product currently being fed through the feeder. Access can be used for secondary operations, such as labeling, scanning, printing, and more.

250ip3 Split Discharge Friction Feeder

Max Run Size: 200mm (w)

Max Product Thickness: 25mm

Available in all four discharge lengths: ED, XED, XLD, SLD

350ip3 Split Discharge Friction Feeder

Max Run Size: 300mm (w)

Max Product Thickness: 25mm

Available in all four discharge lengths: ED, XED, XLD, SLD

550ip3 Split Discharge Friction Feeder

Max Run Size: 500mm (w)

Max Product Thickness: 25mm

Available in all four discharge lengths: ED, XED, XLD, SLD

PRODUCT VIDEO

Our Split Discharge series can feed products of a variety of thicknesses, lengths, and widths. See our friction feeder in action!

Want to see how your product feeds? Request a video demo and send us a sample of your product.

COMMON APPLICATIONS

Below are a few examples of common applications that utilize split discharge. Our

machines all have a wide variety of applications, so please reach out if you have a question

regarding your specific application and we will find the right solution for you!

UDI Labeling

Boxes

Security Labels

Scratch off Labels & Cards

Looking for spare parts?

Current customers get access to our online store, the Parts Portal, for convenient and fast online ordering of spare parts and accessories.