Keeping Things Moving: Upgrade Your Automation System with Conveyors

One of the most significant advantages of automating, or even partially automating a process, is the time saved by allowing workers to focus on more than one task or eliminating the need for human workers altogether. An uninterrupted process is a significant factor in successful production. From simple to complex automation systems, conveyors keep things moving within the system and in some cases even extend the system’s capacity and runtimes. A conveyor can be a silent hero of a system but the wrong conveyor can be an obtrusive nuisance that needs constant attention and upkeep.

It could be time to upgrade or replace your conveyor if:

- It requires more maintenance than normal

- Certain sections of the system consistently have problems

- Products are coming out of the system damaged

- You’ve changed your products or capacity needs

Choosing the Right Conveyor

A company’s product shapes the automation system; everything from the size, shape, texture, fragility, and more needs to be factored into the creation of an automation system. In the end, delivering a high-quality product to customers is the top priority for any company. The automation system should be built to fit the application, not the other way around.

There are many things to consider when buying a new conveyor or replacing an existing one:

- What is your product?

- What are your size requirements?

- What is your application?

- What is your budget?

There are multiple types of conveyors available to fit your specific application and system. Finding the right one can be the difference between a smooth process and a lifetime of troubleshooting and maintenance. While it’s best to be informed about the different types of conveyors, our automation experts can help you choose the best conveyor for your application.

Types of Conveyors

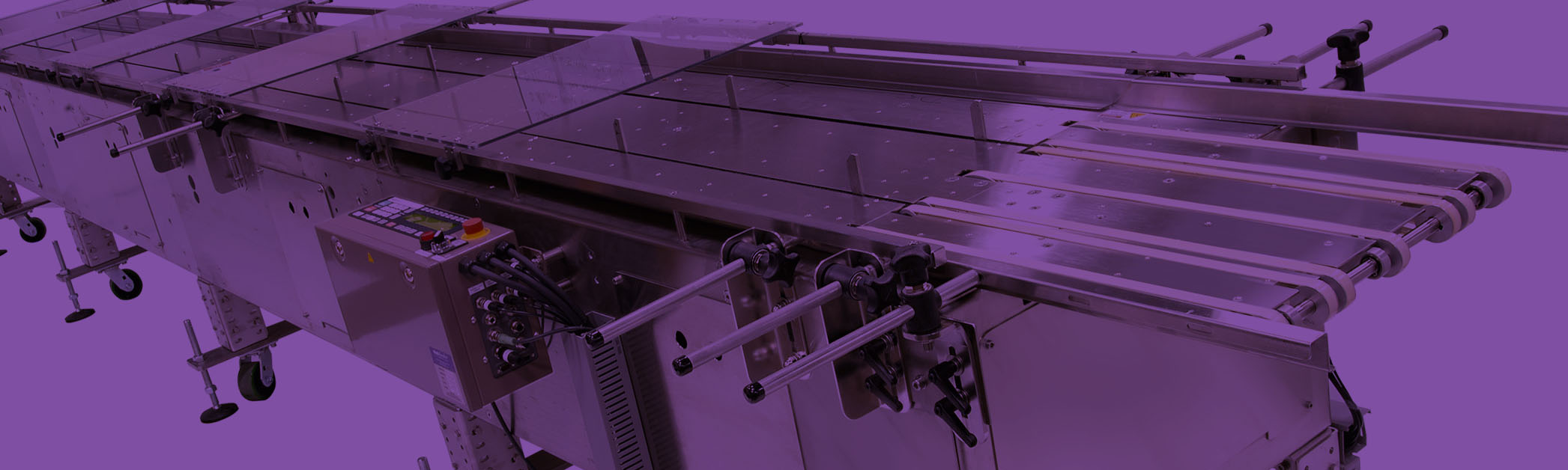

Vacuum Track Conveyor

The Vacuum Track Conveyor (VTC) is a standard option. Using suction force, the VTC controls products as they move down the conveyor. Even irregularly shaped products are easy to control when they are spread out flat on a horizontal surface. Vacuum track conveyors have multiple configurations to fit different applications. The open surface and linear mounting bars provide quick mounting and access for optional components, such as inkjet or laser coders, scanners, vision systems, and more.

High-speed tipping is the ideal application to use the vacuum track conveyor. Tipping is a common automation term describing when you take two products and join them together with one product (tipping product) on top of another product (base product). Glue or other kinds of adhesive are used to keep the two products together. Tipping requires an open surface for access to the base product and mounting the friction feeder over the top to dispense the tipping product. The vacuum track conveyor offers precise control of the base product that is needed for accurate tipping.

Shingling Conveyor

The Shingling Conveyor accumulates batches of products for convenient operator removal. Usually found at the end of a system, the processed products on the Shingling Conveyor do not need immediate attention, adding capacity to the system and extending the run times. The shingling conveyor moves at a slower rate than the rest of the system, causing the products to shingle and stack up on the conveyor.

Batching flat products, such as booklets, brochures, and or even filled pouches, is a common application for the shingling conveyor. These batches can be queued up for removal or to be transported to the next step of the system. The spacing of the shingled products can be easily adjusted by changing the speed of the conveyor.

High-Speed Collator

The High-Speed Collator (HSC) is an open-face conveyor that utilizes lugs to handle firmly, control, and transport products down a conveyor. Products automatically transfer onto a belted takeaway and the lugs can be spaced and timed to match a downstream transport. The HSC has an open surface, making it ideal for mounting components, such as barcode scanners and vision systems, over the conveyor.

The lugs of the HSC lend themselves incredibly well to the application of stacking and batching. The High-Speed Collator System uses friction feeders to feed different types of product into a drop table to form a stack that is dropped onto the conveyor. The lugs move the stack to the next friction feeder for the Drop Table to add to the stack. The collation of papers is moved to the next step of the system with the lugs keeping the stack square.

Automatic Product Loader (APL)

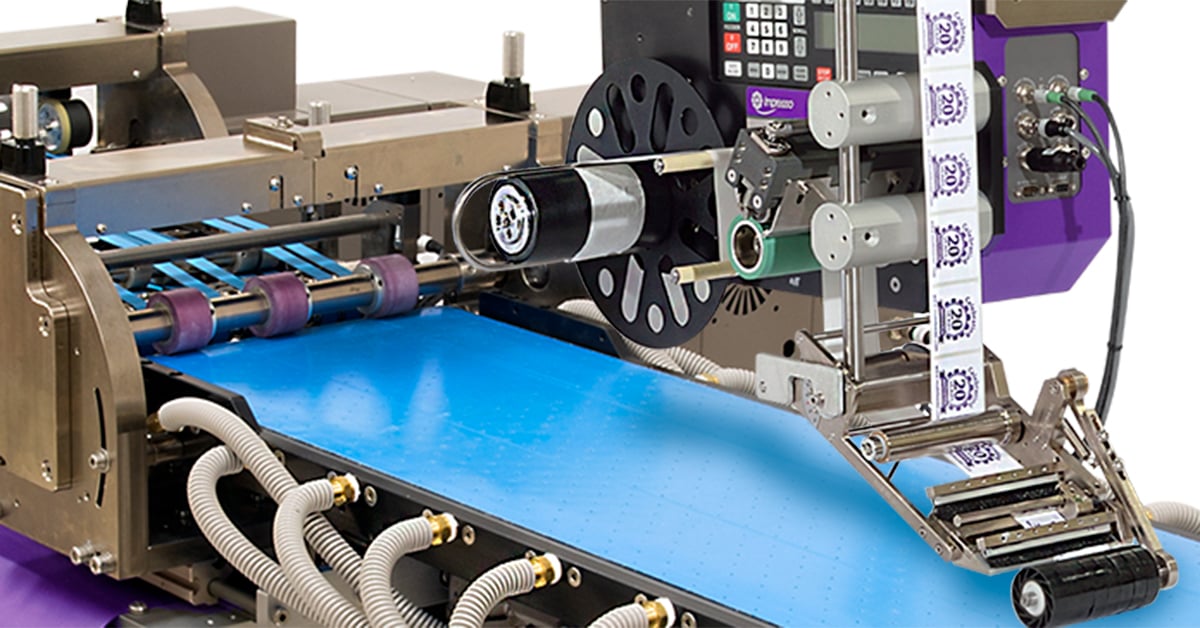

The Automatic Product Loader (APL) is a special conveyor that extends a friction feeder’s production capacity and, in turn, the system’s run times. Designed specifically for MFT Friction Feeders and their automation systems, products are spread horizontally over the APL’s surface instead of stacked vertically in the feeder. This method of loading the product is perfect for irregularly shaped products and increases the capacity of the friction feeder.

Irregularly shaped products have problems stacking vertically in the friction feeder. The APL is ideal for these irregularly shaped products. For example, plastic bags with a zipper do not stack well vertically. The zipper makes the stack uneven, which leads to jams and skewed products coming through the friction feeder. The APL has the product spread horizontally on the conveyor that feeds into the friction feeder eliminating the need for a stack. Even standard products benefit from an APL as they can easily be loaded onto the APL to expand the friction feeder’s capacity and seamlessly extend the run times of the system.

Integrating and Installing Conveyors

Integrating and installing conveyors is the easiest part of the process. Especially if you have experienced and knowledgeable workers helping you! MFT Automation is a one-stop shop for conveyors and automation systems. We work with customers from the first design plans to integration and installation. We have a dedicated team of mechanical engineers and technicians that integrate, test, and fine-tune your systems before installation. We offer on-site installation and training so that everyone is on the same page regarding the automation system. After installation, we have a dedicated aftermarket support team that provides technical phone support, and field service support for troubleshooting, repairs, and more.

MFT Automation

MFT Automation has been helping customers design, build, and integrate high-performance automation solutions for over 25 years. MFT Automation’s equipment, systems, and services are known for their flexibility, accuracy, and performance. Our success is made possible by our engineering-oriented and customer-driven approach to finding the best possible automation solution for customers’ applications. With an abundance of in-house resources including Mechanical Engineering, Electrical Engineering, Software Engineering, and a machine shop with modern CNC and lathe machine tools, we work with customers from the first solution draft to installation and integration. Contact us with your latest automation challenge, online or call us at 1-651-427-1264.