Web Tipping

Web printing is a form of offset printing that can produce a high volume of prints at high speeds. Web printing has printers running continuously while large rolls of paper are fed through the printer. In tipping applications, a friction feeder accurately places a flat tip-on product onto another product moving underneath the feeder (usually on a conveyor). The two products will typically be affixed together using glue sprayed from a hotmelt gluing system. Web tipping is a process where products, such as booklets or folded inserts, are tipped onto a continuous web and then laminated to create multi-layer labels. An example of these multi-layered labels is extended content labels (ECLs). Other examples of web tipping are creating peel-off labels, perfume samples in magazines, extended content labels, and more.

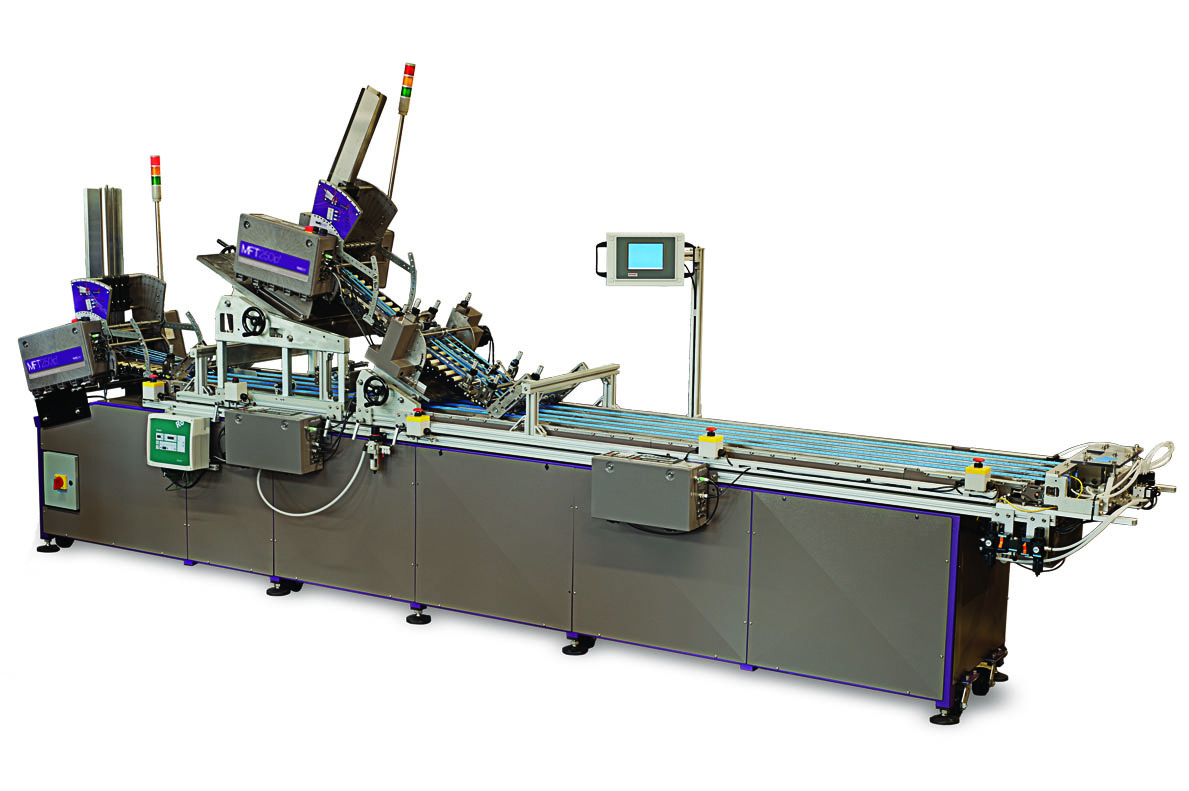

Booklet to Web System

Available in a standard and large format, the Booklet to Web was designed for and patented for web tipping applications. Lead Registration Technique, lug belts square the product on the lead edge for accurate and reliable label placement. Built with the same durable technology as our high-performance friction feeders, the Booklet to Web System meets the challenge of the toughest applications while providing years of steady service.

Accutipping

Accutipping is MFT Automation’s proprietary tipping software engineered specifically for Multifeeder’s state-of-the-art Friction Feeders. Accutipping software makes micro-adjustments to the speed of the products during the feeding cycle to consistently match the spacing of the base products for precise and accurate placement. These small adjustments make a big difference! The Accutipping software allows the system to tip at sustained rates of up to 500 products per minute with accuracies of up to +- 1/32nd of an inch.

MFT Automation

MFT Automation has been helping customers design, build, and integrate high-performance automation solutions for over 25 years. MFT Automation’s equipment, systems, and services are known for their flexibility, accuracy, and performance. Our success is made possible by our engineering-oriented and customer-driven approach to finding the best possible automation solution for customers’ applications. With an abundance of in-house resources including Mechanical Engineering, Electrical Engineering, Software Engineering, and a machine shop with modern CNC and lathe machine tools, we work with customers from the first solution draft to installation and integration. Contact us with your latest automation challenge, online or call us at 1-651-427-1255.

Want to see how your product integrated

with our machines?

Send us a sample and we will make a demo video showing how your products feed through our machines.