Smart Automation. Faster Changeovers. Better Results.

Meet the Next-Generation MFT Tray Former 500.

The MFT Tray Former 500 is designed to keep production lines running smoothly by combining speed, reliability, and efficiency in one compact system. Its thoughtful engineering reduces complexity on the floor, making it easier for operators to keep lines moving and costs down.

Whether used as a standalone solution or as part of a fully automated packaging line, the new MFT Tray Former delivers consistent results that scale with your business and increase ROI.

FEATURES AND BENEFITS

Faster

Changeovers

Switch between products quickly with toolless dies and rams. No tools required and no downtime for cooling.

Less Maintenance,

More Uptime

Drawer-style access to both the die holder and gluer keeps service simple and fast, so your line stays running.

Space-Saving

Design

A compact footprint allows the Tray Former to fit seamlessly into crowded production floors or existing lines.

Simpler

Operation

Straightforward controls and a simple design make the machine easy to learn, run, and maintain.

Reliable, Long-Term

Performance

Built with a welded steel frame and servo-driven precision for consistent operation shift after shift.

SEE THE MFT TRAY FORMER 500 IN ACTION

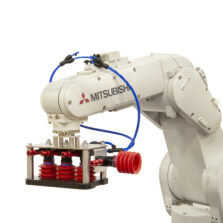

The MFT Tray Former 500 Scales With Your Automation Needs

Integrate with MFT feeders, robotics, and conveyors for a complete packaging line. With advanced safety features and precise counting sensors, it ensures safe, repeatable, and accurate tray forming every time.

Looking for spare parts?

Current customers get access to our online store, the Parts Portal, for convenient and fast online ordering of spare parts and accessories.