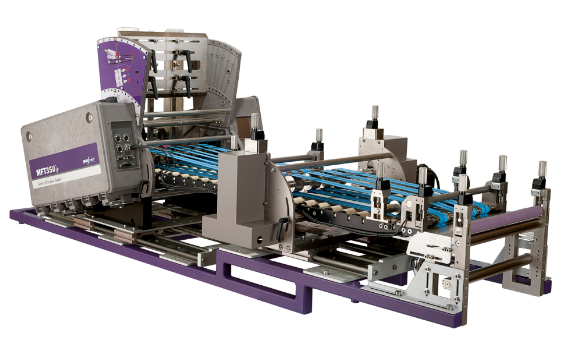

High Performance,

High Speed Production,

Web-Tipping System

The accuracy of a web-tipping application will no longer be measured in fractions of an inch but in fractions of a millimeter. The 1300DHSL is built with the same durable technology as our high-performance friction feeders. Combining proven software with a powerful, robust 750-watt servo-motor (with optional 1000-watt available), and using a zerØ backlash spider coupling, the 1300DHSL web-tipping system effortlessly applies tip-on product to a web at production speeds while providing years of reliable operation. This system can easily be integrated into an existing production line or as part of a complete automation solution using one of our versatile accessories such as the Vacuum Track Conveyor or Automatic Product Loader.

- ZerØ Backlash Spider Coupler

- Precise Ball Screw Actuators

- Siko® Adjustment Dials

- SKF® Sealed Bearings

- Robust 750 Watt Servo-Motor*

- Leading Edge Registration**

*with optional 1000-watt available

**Patent-Pending

- Typical Height – 1337mm (52.6”)

- Typical Length – 1573mm (61.9”)

- Typical Width – 877mm (34.5”)

- Maximum Belt Speed – 200 Meters per Minute*

- Power Requirements – 200 – 240 V single phase 50-60Hz

- Operating Temperature – 10°-35°C (50°-95°F)

*Application-Dependent

- Minimum Size – 38mm (W) x 25mm (L)

- Maximum Size* – 300mm (W) x 325mm (L)

- Minimum Thickness – .05mm

- Maximum Thickness – 25mm

*All Multifeeder Technology equipment can be designed to meet specific production requirements

- Automatic Product Loader

- Vacuum Track Conveyor

- Labeling System

- Print-On-Demand System

- Product Verification System

- Product Reject System

- 3-Color Warning Light