Clean in Place Feeding Solution with a Minimal Risk of Contamination

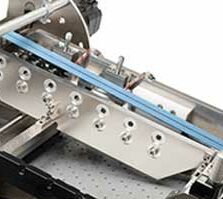

The Hygienic Washdown Series meets sanitary requirements and complies with IP66 or higher as well as NEMA4X standards. The hygienic friction feeder is designed for end-customers in the food industry that need to repetitively and aggressively clean their production floor equipment. This clean in place (CIP) friction feeder is engineered with type 304 stainless steel, powered by a 1200 watt brushless servo motor, and is moisture and corrosion resistant and meets FDA standards. The open design allows for minimal disassembly for easy cleaning and maintenance. This machine is self-draining and has compatible materials with no hollow areas, which is a principle we follow to ensure the sanitary design and reduced risk of contamination.

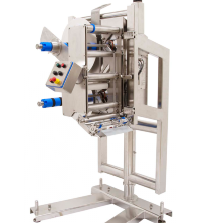

350IP3 Washdown Friction Feeder

350IP3 Washdown Friction Feeder

Max Run Size: 300mm (w)

Max Product Thickness: 25mm

Available in all four discharge lengths: ED, XED, XLD, SLD

550IP3 Washdown Friction Feeder

550IP3 Washdown Friction Feeder

Max Run Size: 500mm (w)

Max Product Thickness: 25mm

Available in all four discharge lengths: ED, XED, XLD, SLD

PRODUCT VIDEO

Our Washdown series can feed products of a variety of thicknesses, lengths, and widths. See our friction feeder in action!

Want to see how your product feeds? Request a video demo and send us a sample of your product.

COMMON APPLICATIONS

Below are a few examples of common applications used with the wasdown feeder. Our

machines all have a wide variety of applications, so please reach out if you have a question

regarding your specific application and we will find the right solution for you!

Medical Test Kits

Credit Cards & Gift Cards

Boxes

UDI Labeling

Looking for spare parts?

Current customers get access to our online store, the Parts Portal, for convenient and fast online ordering of spare parts and accessories.