Join us at WestPack 2023

We’re excited about our first tradeshow of the year! We’ll be exhibiting at WestPack 2023 at Booth #5028. Join us February 9-7, 2023 in Anaheim, California, for the west coast’s largest advance manufacturing tradeshow. WestPack is part of IME West which features five tradeshows on the same expo floor. Packaging is just the tip of the iceberg, from robotics to medtech and more, IME West connects you across multiple verticals and industries.

Use code MYGUEST5028 for a free expo pass and 20% off a 2-day conference pass!

Register here!

Already registered? Add us to your show planner here!

At the Show

Live Demos

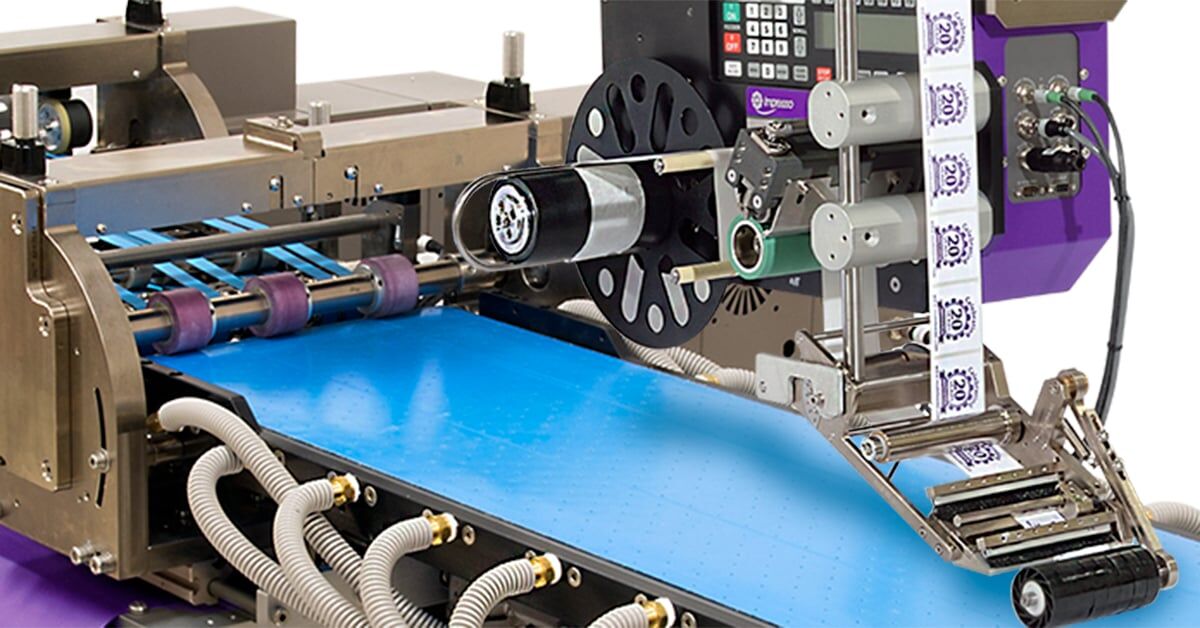

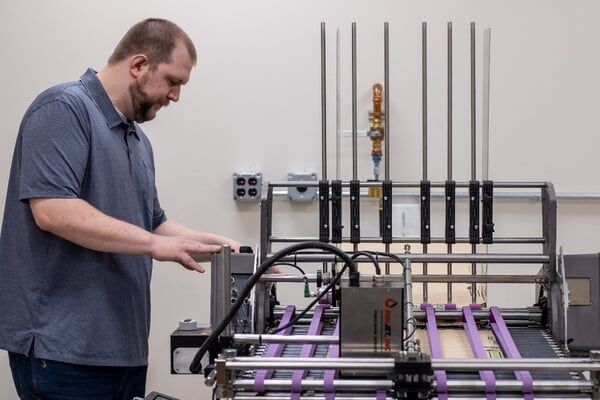

We will be showcasing our Printing and Labeling System featuring our Impresso Labeler with a Videojet Printer. The Impresso is our high-performance pressure sensitive labeler, built for the industrial environments of the packaging industry. With a compact and flexible design, the labeler can be easily integrated into existing production lines and systems or can be its own standalone piece of equipment. The labeler is equipped with a independently powered 1000-watt motor for labeling with repeatable accuracy. The Impresso Labeler features a highly adaptable software package that integrates multiple sensor triggers to achieve accurate label placement at high speeds. The Videojet Printer easily integrates with the Impresso Labeler to condense the printing and labeling process into one powerful system. Come visit us and see live on-demand demos of our Impresso Labeler at Booth #5028!

Pharmaceutic Litho & Label Company (PLLC) will also be showcasing our MFT 350 ip3 Friction Feeder at their booth! Part of MFT Automation’s Industrial Performance (ip) series of friction feeders, the 350 ip3 is a mid-size option with a small footprint that easily integrates into existing production lines or stands on its own. The ip3 series features a powerful 750-watt brushless servo motor (optional 1000-watt available) and hardened stainless steel shafts and sealed bearings for maximum life expectancy and long production runs. You can see our friction feeder in action at Pharmaceutic Litho & Label Company’s Booth #1783.

Meet the Team

Mike Emola – Sales Manager

Mike has 15 years of sales experience spanning technology & automation bringing a client-focused, consultative approach. When Mike isn’t in the office you can probably find him out on the lake with his wife and three kids or entertaining family and friends with good food. Connect with Mike on LinkedIn before the show!

Todd Rice – Regional Sales Manager

Meet our West Coast representative, Todd Rice. Todd has over 25 years of experience in the packaging and labeling industry and is excited to share his wisdom to help customers solve their automation challenges. When Todd isn’t in the office, he enjoys golfing and deep-sea fishing off the Pacific Coast and Mexico. Connect with Todd on LinkedIn before the show!

Jim Iler – Regional Applications Manager

Jim has been with MFT Automation for 19 years and is ready to help identify the perfect automation system for your application. When Jim isn’t helping clients improve productivity with automation, he enjoys being outdoors with his friends and family, snowboarding, deer hunting, ice fishing, and camping! Connect with Jim on LinkedIn before the show!

About MFT Automation

MFT Automation is a privately held company that provides high-performance automation solutions throughout the world. With state-of-the-art control technology and robust mechanics, our products feed more quickly and accurately to provide customers with a greater return on investment. All of our standard equipment including, friction feeders, labelers, and accessories can easily be integrated with other machines to provide a total system solution for any application. With experience in industries such as pharmaceutical, food, packaging, printing, financial/security, and fulfillment, MFT Automation can help any sized business with production efficiency.

See the other trade shows we’re attending: mftautomation.com/tradeshow

Keeping Things Moving: Upgrade Your Automation System with Conveyors

One of the most significant advantages of automating, or even partially automating a process, is the time saved by allowing workers to focus on more than one task or eliminating the need for human workers altogether. An uninterrupted process is a significant factor in successful production. From simple to complex automation systems, conveyors keep things moving within the system and in some cases even extend the system’s capacity and runtimes. A conveyor can be a silent hero of a system but the wrong conveyor can be an obtrusive nuisance that needs constant attention and upkeep.

It could be time to upgrade or replace your conveyor if:

- It requires more maintenance than normal

- Certain sections of the system consistently have problems

- Products are coming out of the system damaged

- You’ve changed your products or capacity needs

Choosing the Right Conveyor

A company’s product shapes the automation system; everything from the size, shape, texture, fragility, and more needs to be factored into the creation of an automation system. In the end, delivering a high-quality product to customers is the top priority for any company. The automation system should be built to fit the application, not the other way around.

There are many things to consider when buying a new conveyor or replacing an existing one:

- What is your product?

- What are your size requirements?

- What is your application?

- What is your budget?

There are multiple types of conveyors available to fit your specific application and system. Finding the right one can be the difference between a smooth process and a lifetime of troubleshooting and maintenance. While it’s best to be informed about the different types of conveyors, our automation experts can help you choose the best conveyor for your application.

Types of Conveyors

Vacuum Track Conveyor

The Vacuum Track Conveyor (VTC) is a standard option. Using suction force, the VTC controls products as they move down the conveyor. Even irregularly shaped products are easy to control when they are spread out flat on a horizontal surface. Vacuum track conveyors have multiple configurations to fit different applications. The open surface and linear mounting bars provide quick mounting and access for optional components, such as inkjet or laser coders, scanners, vision systems, and more.

High-speed tipping is the ideal application to use the vacuum track conveyor. Tipping is a common automation term describing when you take two products and join them together with one product (tipping product) on top of another product (base product). Glue or other kinds of adhesive are used to keep the two products together. Tipping requires an open surface for access to the base product and mounting the friction feeder over the top to dispense the tipping product. The vacuum track conveyor offers precise control of the base product that is needed for accurate tipping.

Shingling Conveyor

The Shingling Conveyor accumulates batches of products for convenient operator removal. Usually found at the end of a system, the processed products on the Shingling Conveyor do not need immediate attention, adding capacity to the system and extending the run times. The shingling conveyor moves at a slower rate than the rest of the system, causing the products to shingle and stack up on the conveyor.

Batching flat products, such as booklets, brochures, and or even filled pouches, is a common application for the shingling conveyor. These batches can be queued up for removal or to be transported to the next step of the system. The spacing of the shingled products can be easily adjusted by changing the speed of the conveyor.

High-Speed Collator

The High-Speed Collator (HSC) is an open-face conveyor that utilizes lugs to handle firmly, control, and transport products down a conveyor. Products automatically transfer onto a belted takeaway and the lugs can be spaced and timed to match a downstream transport. The HSC has an open surface, making it ideal for mounting components, such as barcode scanners and vision systems, over the conveyor.

The lugs of the HSC lend themselves incredibly well to the application of stacking and batching. The High-Speed Collator System uses friction feeders to feed different types of product into a drop table to form a stack that is dropped onto the conveyor. The lugs move the stack to the next friction feeder for the Drop Table to add to the stack. The collation of papers is moved to the next step of the system with the lugs keeping the stack square.

Automatic Product Loader (APL)

The Automatic Product Loader (APL) is a special conveyor that extends a friction feeder’s production capacity and, in turn, the system’s run times. Designed specifically for MFT Friction Feeders and their automation systems, products are spread horizontally over the APL’s surface instead of stacked vertically in the feeder. This method of loading the product is perfect for irregularly shaped products and increases the capacity of the friction feeder.

Irregularly shaped products have problems stacking vertically in the friction feeder. The APL is ideal for these irregularly shaped products. For example, plastic bags with a zipper do not stack well vertically. The zipper makes the stack uneven, which leads to jams and skewed products coming through the friction feeder. The APL has the product spread horizontally on the conveyor that feeds into the friction feeder eliminating the need for a stack. Even standard products benefit from an APL as they can easily be loaded onto the APL to expand the friction feeder’s capacity and seamlessly extend the run times of the system.

Integrating and Installing Conveyors

Integrating and installing conveyors is the easiest part of the process. Especially if you have experienced and knowledgeable workers helping you! MFT Automation is a one-stop shop for conveyors and automation systems. We work with customers from the first design plans to integration and installation. We have a dedicated team of mechanical engineers and technicians that integrate, test, and fine-tune your systems before installation. We offer on-site installation and training so that everyone is on the same page regarding the automation system. After installation, we have a dedicated aftermarket support team that provides technical phone support, and field service support for troubleshooting, repairs, and more.

MFT Automation

MFT Automation has been helping customers design, build, and integrate high-performance automation solutions for over 25 years. MFT Automation’s equipment, systems, and services are known for their flexibility, accuracy, and performance. Our success is made possible by our engineering-oriented and customer-driven approach to finding the best possible automation solution for customers’ applications. With an abundance of in-house resources including Mechanical Engineering, Electrical Engineering, Software Engineering, and a machine shop with modern CNC and lathe machine tools, we work with customers from the first solution draft to installation and integration. Contact us with your latest automation challenge, online or call us at 1-651-427-1264.

How to Automate your UPC Labeling and Tracking Process

Keeping track of inventory is one of the top priorities of internal operations for any business. A common way stores and companies track inventory is with barcodes which can be scanned to identify the product and its price. With barcode labels, products can be tracked from production to the point of sale, or even to contact a customer if there is a major recall on the product. There are two major types of barcodes used in the world.

Universal Product Codes (UPC)

Universal Product Code (UPC) is a unique 12-digit number assigned to a product or item by the Global Standards Organization (GS1). The GS1 manages global barcode standards, as companies cannot create their own UPC numbers. UPCs are widely known as the primary way businesses track inventory. The basis for UPCs was created by a group of trade associations from the grocery industry to increase efficiency while stocking shelves and decreasing check-out times at their grocery stores. Now, each industry dictates its own requirements for the UPCs. Though not legally required, UPCs are usually necessary to sell through traditional retailers and online marketplaces like Amazon, Walmart, and more.

UPCs are made up of a country code number (the code for USA and Canada is zero (0)), a company number code, and a product number code. With these parameters, there are billions of UPCs in the world with each company having hundreds to thousands of UPCs in its inventory. Each product and its variations need its own unique UPC code. For example, for every t-shirt design, there are size variations from extra small to extra large, meaning a company needs five UPCs (one for each size) for just one t-shirt design.

International Article Numbers (EAN)

The rest of the world uses International Article Numbers (also known as European Article Numbers or EANs) to track their products. With the popularity of UPCs growing in other countries, EANs were created to increase the number of codes for the different European, Asian, and African countries. The GS1 organization also assigns the EANs to companies. EANs have 13 digits and countries have specific codes while the USA and Canada’s country code is zero (0). Multinational companies can have both UPCs for their products sold in USA and Canada and EANs for products sold internationally.

Best UPC Practices

The main advantage of barcodes is their scannability, made for quick data capture and unobtrusiveness on the packaging. The barcode has to be readable otherwise it will not scan and important data tracking data can be lost. Let’s quickly cover some best practices and standards for your UPC labels:

To guarantee readability, UPCs must follow specific design standards. First, The area on the left and right side of the UPC barcode is required to be free of all printing. This area is known as the ”Quiet Zone”. Quiet zones are required on both ends to read the barcode from either direction to prepare the scanners for the barcode and tell the scanner when to stop.

The level of contrast between the background and barcode bars is important to maintain readability. In the same vein as contrast, the transparency of the package can cause problems. Transparent packaging, such as plastic bags or containers can be problematic as barcodes have trouble being read on the transparent material. It’s recommended that the background of the UPC on transparent packages be opaque white to increase the contrast with the dark bars.

The standard size of a UPC code is 1.469 inches wide by 1.02 inches high, including all the numbers on the bottom. The maximum recommended size, 200% of the standard size, is 2.938″ w x 2.04″ h. The minimum recommended size is 80% of the standard size or 1.175″ w x .816″ h.

The best location to place UPC barcodes on the product is anywhere that is easy to scan and find. Generally, UPCs are located on the bottom or backside of a product so the barcode doesn’t conflict with the packaging design. Though recent advancements in sensor and scanning technologies have boosted a new design trend of creatively incorporating the barcode into the packaging’s design. These vanity barcodes are still functional but they come in odd shapes and different colors and extraneous designs. But most companies stick to the standard design and many industries set their own specific standards for design and location.

Labeling

Large companies with mass-marketed products often integrate UPCs into the packaging design but small businesses might not have the resources. Labeling is a fast and cost-effective way to apply UPCs to your products. MFT Automation has a wide range of high-performance labelers for automating your UPC and barcode labeling process. From high-speed labelers to print and apply labelers, MFT Automation has a barcode labeler to fit your labeling needs. Compact and modular, our labelers are built to seamlessly integrate into existing production lines.

Impresso Series

MFT Automation’s Impresso Labeler is small and compact for maximum flexibility and can be easily integrated into existing production lines or exist as a piece of standalone equipment. The state-of-the-art, high-performance labeler features a 1000-watt brushless servo motor for efficient unwinding and rewinding and durable stainless steel shafts provide maximum life expectancy.

High-Speed Modular Series

Most companies have a high volume of products to label with barcodes and UPC labels. A high-speed barcode label applicator will help you keep up with demand. With independently powered, synchronized servo drive motors for unwind, rewind, and drive, the High Speed Modular (HSM) series can function at high speeds while maintaining accuracy and precision while placing labels. Flexible and compact, the HSM series can be easily integrated into existing systems or be a standalone piece of equipment without sacrificing space in your production lines.

Print and Apply Labeler

The MFT Print and Apply Labeler system prints and adheres labels to most flat surfaces from packaging, and cartons to folders, pouches, and more. Print and apply labeling is a good technique for barcode labeling as it can print UPC and barcode labels on demand. The system has a modular design with the ability to use different print engines for the customization of print quality. Customization gives the option to match the printing engine to a customer’s existing print engine so there is no learning curve in maintenance for a new print engine, making it perfect for labeling applications.

Track and Trace System

Integrate one of our high-performance labelers into our innovative Track and Trace system. The Track & Trace system offers turnkey product handling for serialization coding/printing, and an inspection and rejects system providing a trackable data file. A powerful infrared sensor allows for accurate count using double-detect and overlap detection. This integrated manufacturing system is equipped with a highly adaptable software package that ensures flexible and precise controls.

MFT Automation

MFT Automation has been helping customers design, build, and integrate high-performance automation solutions for over 25 years. MFT Automation’s equipment, systems, and services are known for their flexibility, accuracy, and performance. Our success is made possible by our engineering-oriented and customer-driven approach to finding the best possible automation solution for customers’ applications.

With an abundance of in-house resources including Mechanical Engineering, Electrical Engineering, Software Engineering, and a machine shop with modern CNC and lathe machine tools, we work with customers from the first solution draft to installation and integration. Contact us with your latest automation challenge, online or call us at 1-651-427-1255.

Join us at PACK EXPO International 2022

MFT Automation is excited to be exhibiting at PACK EXPO International 2022. Join us October 23-26, 2022 in Chicago, IL for one of the world’s largest packaging & processing tradeshows. You can find us at Booth #5410 in the North Hall.

Add us to your show planner: https://packexpo22.mapyourshow.com/8_0/exhibitor/exhibitor-details.cfm?exhid=02002142

Use code 91W64 for FREE registration for the show or follow the link below!

https://pei22.nvytes.co/lp22/91W64.html

Keep up to date on the latest and greatest innovations in the packaging industry and network with experts, suppliers, and more at this year’s biggest packaging and processing show! PackExpo International brings together people from 40+ vertical markets making it easy to explore ideas from other industries and build relationships with new and different experts and peers.

At the Booth

Booklet to Web

Our web-tipping system effortlessly applies tip-on products to a web at high production speeds while providing years of reliable operation. Featuring our robust ip3 Friction Feeder and our high-performance IMPRESSO Labeler, the Booklet to Web System combines proven software with a powerful, robust 800-watt servo-motor, and using a zerØ backlash spider coupling into one comprehensive and productive system. See the system’s reliable accuracy in action during our live demonstrations at the show!

Impresso Labeler and Friction Feeder System

Our IMPRESSO Labeler and Friction Feeder System utilize an ip3 series friction feeder and our innovative IMPRESSO labeler in a compact configuration that allows the System to be highly mobile and have a cost-effective footprint. The Labeler and Friction Feeder System’s intuitive and easy-to-reach single-sided controls provide exceptionally efficient operation. Designed for long production runs, the IMPRESSO Labeler and Friction Feeder System provide years of uninterrupted and quality service.

Roll-to-Sheet Cutting System

The Roll-to-Sheet Cutting System incorporates a module-speed unwind web feeding to a driven discharge cutter system that is ideal for a variety of cutting and placing applications. The servo-driven roll unwind and driven discharges combine to make lightning-fast feeding and cutting. The system maintains consistent light web tension by signaling the unwind to release more product as the driven discharges move the web through the system. The speed and accurate placement and cutting of sheets, film, wrap, soaker pads, or other material is maximized via a fast and accurate shearing blade motion of the pneumatic guillotine cutter (320mm cutting area), and pneumatic air blast pad transfers. Set up and operation is easy, with roll capacities maximums reaching 22 inches (diameter) or 150 lbs.

Robotic Integration

We’re excited to be showcasing our knowledge in Automation Robotics. Partnering with Mitsubishi Electric, we have taken a deep dive into how to integrate robotics into our total system solutions. Our robotic capabilities range from simple pick-and-place applications to more complex packaging needs. Robotic integration brings many benefits to any packaging line and is the perfect piece to finish off a fully integrated system. Stop by our booth to see our automation and robotics knowledge in action with a live demo of a robotic arm!

About MFT Automation

MFT Automation is a privately held company that provides high-performance friction feeding and labeling solutions throughout the world. With state-of-the-art control technology and robust mechanics, our products feed more quickly and accurately to provide customers with a greater return on investment. All friction feeders, labelers, and accessories can easily be integrated with other machines to provide a total system solution for any application. With experience in industries such as pharmaceutical, food, packaging, printing, financial/security, and fulfillment, MFT Automation can help any sized business with production efficiency.

See the other tradeshows we’re attending: mftautomation.com/tradeshow

The Best Automated Labeling Method for High Speed Labeling

Manually labeling products works fine at a small production volume but once production increases even slightly, labeling becomes a monumental and tedious task. Automating a labeling system can seem like a daunting investment but the increase in productivity and savings on wages makes the return on investment worth it. Depending on the application, budget, and demand, high-speed labeling is a valuable option for companies to increase their productivity. High-speed labeling is an option for most applications, including labeling boxes, bottles, scratch-off games, Unique Device Identification (UDI) codes, Universal Product Codes (UPC), and more.

There are several automatic labeling methods, but which one is best for high-speed labeling?

Print and Apply Labeling

Comparatively to other labeling techniques, which use pre-printed labels on a roll, the Print and Apply technique has the labels printed on demand and then applied to the product. Depending on the application, Print and Apply labelers use the wipe-on or tamp-on techniques to apply the labels. But printing new labels for every product, in most cases no matter how fast the printer, slows the labeling process down compared to pre-printed labels on a roll. The Print and Apply method is not recommended for high-speed labeling applications.

Tamp Labeling

The Tamp label application uses air and a tamp pad to apply labels. The Tamp technique uses vacuum suction to hold the label to the tamp pad until the product arrives underneath via a conveyor belt. The tamp pad presses the label onto the product as it passed on the conveyor belt. With the tamp technique, the smaller the label the faster the tamp pad can place the label. MFT Automation’s Smart Tamp technique accommodates for variation of heights of boxes with a spring-loaded tamp pad that adjusts to the needed height.

Dispense and Wrap Labeling

The dispense and wrap labeling technique is used when wrapping labels around a product. It is most commonly used for labeling cylindrical products such as bottles of varying sizes, vials, and straight-sided buckets. The product is initially captured in a wrap belt with a stationary backup pad or 3-roller configuration and begins to rotate. While rotating, the label is dispensed off the peel plate in-between the rotating device and the product. The label is fully adhered to during the rotation of the product. While the dispense and wrap technique is the most efficient and accurate way to label cylindrical products, it is not the most efficient or effective way to label non-cylindrical products.

Wipe On Labeling

Wipe-on is a commonly used pressure-sensitive labeling technique. The label is applied while the product is moving and the label applicator itself often matches the speed of the product as it travels down the conveyor. As the product reaches the labeler, it dispenses the label off the peel plate and the label is wiped onto the product. This labeling technique is often used for oval, square, rectangular, and some irregularly shaped products. Wipe-on is the preferred method for high-speed applications due to its simplicity.

Challenges with High-Speed Labeling

Accurate placement of labels is often a top priority in labeling applications. While wipe-on labeling has the most accurate placement rate of the methods, the high speeds still affect it. Accuracy is dependent on many factors including, maintaining constant tension on the roll of labels as it unwinds to dispense the labels. The tension comes from the dancer arms that maintain tension during unwinding/rewinding of the label roll. High-Speed labelers utilize strong motors to respond quickly to rapid changes in dancer arm position, maintaining tension at high speeds for accurate placement at the peel plate. Accuracy is also dependent on the labeler’s ability to adjust speeds quickly to match the variable speed of the conveyor belt. Adjusting speed can put a lot of strain on the motors as they have to react quickly to match the speed of the conveyor and products.

At high speeds, label rolls tend to be finished faster than when labeling at normal speeds. To keep up with the rate the rolls are used up, companies try to solve the problem by buying rolls with more labels. But just finding the largest roll of labels possible can be dangerous. If the roll of labels exceeds the labeler’s capacity it can have major consequences. Overworking the drive motors can shorten the lifespan of the motor as well as the other parts of the machine. There is also a high risk of damaging the labeler structure with an overweight label roll.

103 HSM+ Labeler

The 103 High-Speed Modular (HSM) Labeler is a high-performance labeler built for high-speed labeling applications. Equipped with three independently powered synchronized servo drive motors for unwinding, label placement, and rewind, the 103 HSM quickly adjusts labeling speed to match the speed of the product as it travels down the conveyor. Speed matching is vital for accurate label placement. Three motors also distribute the load and increase the labeler’s load capacity. Designed for flexibility, this small, compact labeler works as a stand-alone piece of equipment or can easily be integrated into existing production lines.

With over 25 years of experience innovating high-performance automation solutions, MFT Automation is your solution partner for your next automation challenge. Equipped with a diverse team of mechanical, electrical, and software engineers and a modern machine shop, MFT Automation works with you every step of the way from design concept to integration, to create the best solution for your application. Contact us for your next labeling project.

Join us at LabelExpo Americas 2022

MFT Automation will be exhibiting at LabelExpo Americas 2022! Join us in Chicago, IL, September 13-15. LabelExpo Americas is part of a global series of label and packaging print events that connect the global print and packaging industry. This three-day event brings together major players in the North American labeling and packaging industries including printers/converters, brand owners, designers, suppliers, and more. LabelExpo Americas is a brilliant showcase of the latest innovations and trends in the industry. Visit us at Booth #3802!

Learn more about LabelExpo: labelexpo-americas.com/exhibitor/mft-automation

Robotics in the Food Packaging Industry

The fast-paced food packaging industry works hard to keep up with the growing demands of consumers and recently has been trying to overcome the recent global events and concerns. The COVID-19 pandemic has increased public interest in food safety with many consumers demanding transparency and pushing for more regulations and requirements for food packaging. This public outcry has incentivized companies to eliminate even more human contact from their food packaging production lines. To meet the growing food safety and output demands of consumers, the food packaging industry is once again turning towards more automation. Let’s explore some of the applications and trends in the food packaging industry.

MFT Automation is a proud Diamond Partner with Mitsubishi Electric Automation. We provide a robotic, end-of-arm tooling option for a wide variety of packaging solutions.