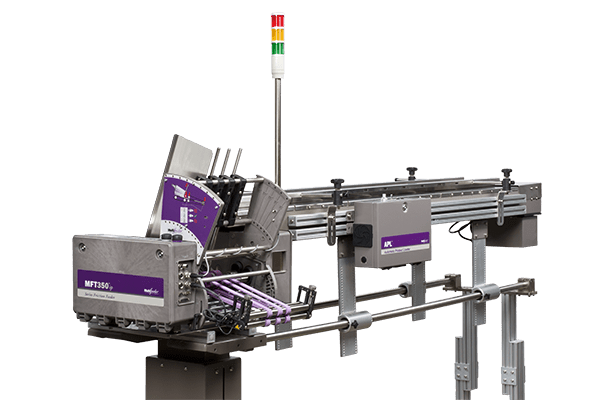

Fewer Operators,

Uninterrupted Production,

Increased throughput

Uninterrupted production is the key to successful manufacturing. The MFT Automatic Product Loader multiplies the product capacity of the MFT Feeder Systems. This addition maximizes the runtime between product reloads while minimizing the number of operators require to run the system, keeping production lines flowing. MFT APLs are also used when the shape of the product itself doesn’t allow for a production stack height. Imagine a plastic bag enclosed at one end. How high can it be stacked vertically before becoming unstable? With an APL that same product can be easily spread horizontally across a flat surface. Another advantage of using an APL, better control of irregular product such as a packaging carton. The APLs are available in a variety of widths and lengths giving you the best configuration for your application requirements. Contact one of our experienced Application Engineers today for complete details about this and other MFT Automation solutions.

Capacity Multiplier

Provides a larger load capacity for longer runtime between reloads

Feed-on-Demand

Supplies the exact amount of product by the friction feeder

Product Control

Gives the ability to load irregular product at larger capacities than standard methods

Smooth Operation

30mm support rods and linear bearings allow the APL to be easily adjusted

Less Intervention

With a larger product capacity less operator intervention and operators are required.